Green Pin® Sling Shackle FN

High load capacity bow shackle with safety bolt and fixed nut

- Saves on cost of wire/synthethic rope due to less wear

- Triple safety (split pin, safety bolt, fixed nut)

- Top choice when the load is dynamic or exposed to extreme vibrations

- Galvanization assures long-term durability

- Shackles of 75T and higher include a Lloyd's proofload test certificate

The Green Pin® Sling Shackle FN is a high load capacity, bow shackle with a safety bolt and a fixed nut. The Sling Shackle FN is an excellent choice for heavy lifting projects due to the shape of the shackle crown. Compared to the standard Green Pin® Heavy Duty Shackles, Sling Shackles have an increased bow radius to improve your sling#s resistance to wear and tear and enable you to use a lighter wire rope to lift the same heavy load. This means that by using the Green Pin® Sling Shackle FN you save on wire rope costs (the Green Pin® Power Sling shackle offers even bigger savings however). Moreover, because of its triple safety (split pin, safety bolt and fixed nut) the shackle is the top choice among Sling shackles when the load is dynamic or exposed to extreme vibrations. The fixed nut of the Green Pin® Sling Shackle FN is drilled through both the shackle nut and pin and is firmly attached to the pin head with bolts and Nord-Lock® washers. Of course, galvanization of the Green Pin® Sling Shackle FN ensures long-term durability. A wide range of certifications is also available: sling shackles of 75 tons and higher include a Lloyd's proofload test certificate for example. The Green Pin® Sling Shackle FN is available in a range with a working load limit from 7 up to 150 tons.

More-

ProductcodeP-6013

-

Materialbow and pin alloy steel, Grade 8, quenched and tempered

-

Safety factorMBL equals 5 x WLL

-

Finishshackle bow painted silver, pin painted green (7 up to 55 ton shackles are hot dipped galvanized)

-

Temp. range-40°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- MTCb

- LROS

- MPIb

- USb

- CE

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

Weight shackle pin

(kg)

|

Weight shackle pin

(lb)

|

diameter body

(mm)

A

|

diameter body (inch)

A

|

diameter pin

(mm)

B

|

diameter pin (inch)

B

|

diameter eye (inch)

C

|

diameter eye

(mm)

C

|

width eye

(mm)

D

|

width eye (inch)

D

|

width inside

(mm)

E

|

width inside (inch)

E

|

length inside

(mm)

F

|

length inside (inch)

F

|

width bow

(mm)

G

|

width bow (inch)

G

|

length

(mm)

H

|

length (inch)

H

|

length bolt

(mm)

I

|

length bolt (inch)

I

|

width

(mm)

J

|

width (inch)

J

|

thickness nut (inch)

K

|

thickness nut

(mm)

K

|

bearing surface (inch)

L

|

bearing surface

(mm)

L

|

Securing bolt thread

(inch)

M

|

Securing bolt thread

(mm)

M

|

securing bolt length (inch)

N

|

securing bolt length

(mm)

N

|

Torque

(nm)

|

Torque

(nm)

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0007FN | 7 | 0,99 | 22 | 22 | 46 | 19 | 32 | 96 | 64 | 153 | 115 | 110 | 19 | 41 | M6 | 45 | 9,2 | 1.97 | |||||||||||||||||||

| SLGPF0007FN | 7 | 2,18 | 7/8 | 7/8 | 1 13/16 | 3/4 | 1 9/32 | 3 25/32 | 2 17/32 | 6 | 4 17/32 | 4 5/16 | 3/4 | 1 5/8 | M6 | 1 3/4 | 9,2 | 4.34 | |||||||||||||||||||

| SLGPF0012FN | 12,5 | 1,82 | 28 | 28 | 61 | 25 | 44 | 120 | 82 | 197 | 151 | 146 | 24 | 54 | M8 | 50 | 22 | 4.27 | |||||||||||||||||||

| SLGPF0012FN | 12,5 | 4 | 1 1/8 | 1 1/8 | 2 3/8 | 1 | 1 3/4 | 4 23/32 | 3 1/4 | 7 3/4 | 5 15/16 | 5 3/4 | 15/16 | 2 1/8 | M8 | 2 | 22 | 9.42 | |||||||||||||||||||

| SLGPF0018FN | 18 | 2,35 | 35 | 35 | 69 | 30 | 54 | 148 | 102 | 239 | 171 | 180 | 29 | 64 | M10 | 65 | 43 | 6.85 | |||||||||||||||||||

| SLGPF0018FN | 18 | 5,18 | 1 3/8 | 1 3/8 | 2 23/32 | 1 3/16 | 2 1/8 | 5 13/16 | 4 1/32 | 9 13/32 | 6 23/32 | 7 3/32 | 1 5/32 | 2 17/32 | M10 | 2 1/2 | 43 | 15.1 | |||||||||||||||||||

| SLGPF0030FN | 30 | 4,23 | 40 | 42 | 90 | 35 | 69 | 165 | 126 | 279 | 207 | 200 | 34 | 79 | M6 | 75 | 9,2 | 12.5 | |||||||||||||||||||

| SLGPF0030FN | 30 | 9,33 | 1 9/16 | 1 21/32 | 3 17/32 | 1 3/8 | 2 23/32 | 6 1/2 | 4 31/32 | 10 31/32 | 8 5/32 | 7 7/8 | 1 11/32 | 3 1/8 | M6 | 2 15/16 | 9,2 | 27.5 | |||||||||||||||||||

| SLGPF0040FN | 40 | 4,32 | 55 | 51 | 109 | 45 | 84 | 199 | 140 | 331 | 252 | 235 | 38 | 97 | M8 | 90 | 22 | 20.3 | |||||||||||||||||||

| SLGPF0040FN | 40 | 9,52 | 2 5/32 | 2 | 4 9/32 | 1 25/32 | 3 5/16 | 7 27/32 | 5 1/2 | 13 1/32 | 9 29/32 | 9 1/4 | 1 1/2 | 3 13/16 | M8 | 3 17/32 | 22 | 44.7 | |||||||||||||||||||

| SLGPF0055FN | 55 | 4,6 | 60 | 57 | 115 | 55 | 90 | 240 | 160 | 389 | 294 | 270 | 45 | 100 | M10 | 100 | 43 | 30.4 | |||||||||||||||||||

| SLGPF0055FN | 55 | 10,14 | 2 3/8 | 2 1/4 | 4 17/32 | 2 5/32 | 3 17/32 | 9 7/16 | 6 5/16 | 15 5/16 | 11 9/16 | 10 5/8 | 1 25/32 | 3 15/16 | M10 | 3 15/16 | 43 | 67.1 | |||||||||||||||||||

| SLGPF0075FN | 75 | 11,39 | 68 | 70 | 126 | 54 | 110 | 290 | 185 | 473 | 317 | 317 | 40 | 120 | M12 | 120 | 75 | 45 | |||||||||||||||||||

| SLGPF0075FN | 75 | 25,11 | 2 11/16 | 2 3/4 | 4 31/32 | 2 1/8 | 4 11/32 | 11 13/32 | 7 9/32 | 18 5/8 | 12 15/32 | 12 15/32 | 1 9/16 | 4 23/32 | M12 | 4 23/32 | 75 | 99.2 | |||||||||||||||||||

| SLGPF0125FN | 125 | 18,59 | 85 | 80 | 156 | 85 | 137 | 366 | 220 | 583 | 413 | 390 | 40 | 150 | M12 | 130 | 75 | 92 | |||||||||||||||||||

| SLGPF0125FN | 125 | 40,98 | 3 11/32 | 3 5/32 | 6 5/32 | 3 11/32 | 5 13/32 | 14 13/32 | 8 21/32 | 22 15/16 | 16 1/4 | 15 11/32 | 1 9/16 | 5 29/32 | M12 | 5 1/8 | 75 | 203 | |||||||||||||||||||

| SLGPF0150FN | 150 | 27,25 | 94 | 95 | 181 | 89 | 147 | 391 | 253 | 648 | 445 | 449 | 50 | 170 | M12 | 140 | 75 | 140 | |||||||||||||||||||

| SLGPF0150FN | 150 | 60,08 | 3 11/16 | 3 3/4 | 7 1/8 | 3 1/2 | 5 25/32 | 15 13/32 | 9 31/32 | 25 1/2 | 17 17/32 | 17 11/16 | 1 31/32 | 6 11/16 | M12 | 5 1/2 | 75 | 309 |

Do you have questions about this product? Don't hesitate to contact us.

Product video

Frequently Asked Questions

Note: Main dimensions, general info and warnings can be found in our latest catalogue.

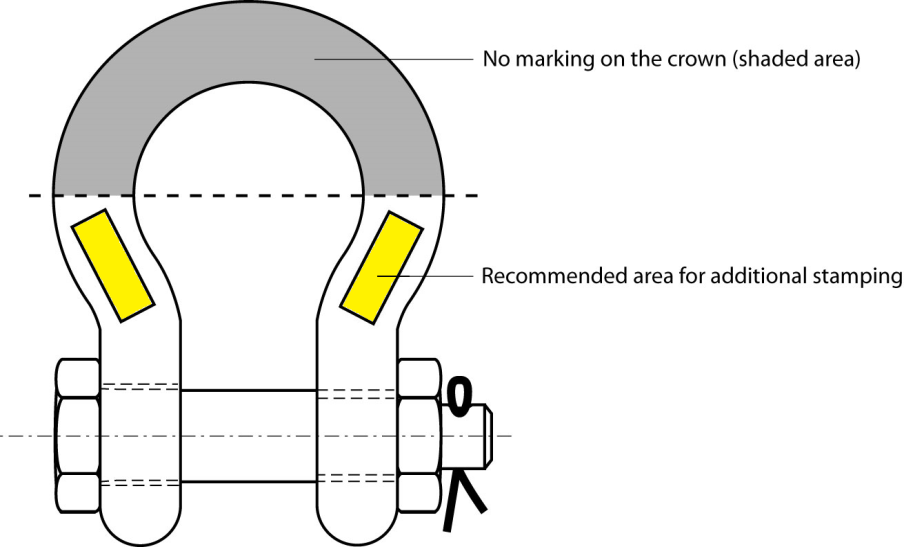

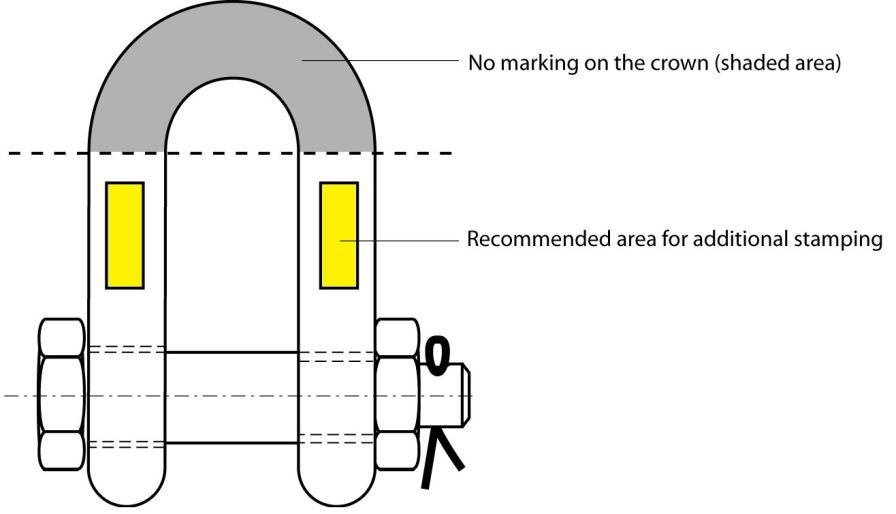

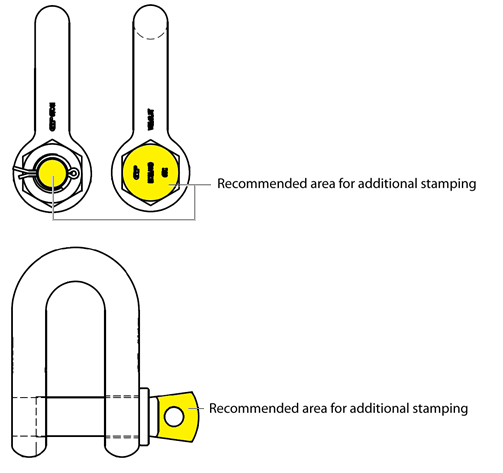

If the recommendations in this product information are followed performance of the shackles is guaranteed:

- permanent identification marks, or symbols, are to be made by dot peen marking or with stamps having rounded profiles (low stress stamps).

- laser markings are allowed as long as the heat of the laser does not influence the material structure and properties in a negative way. The laser marking must be legibly and indelibly marked in a place where the markings will not be removed by use.

- the number of marks on a shackle is to be kept to the minimum.

- the use of fractions and oblique strokes is to be avoided and a dot or hyphen is preferable to a dividing line.

- values of WLL are, generally, to be marked to one place of decimals (except for 0.25 and 0.75) up to 100 t and in integers thereafter. The word “tonnes” may be abbreviated to “t”.

- recommended sizes of marks are

- Diameter of part to be marked > recommended size of mark

- less then 12.5 mm > 3.0 mm

- 12.5 to 26 mm > 4.5 mm

- over 26 mm > 6.0 mm

Typical arrangements of marks can be found in the following illustrations.

FAQ-Reference: PI-05-03. Rev 0.

It is required that shackles are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure. Inspection should take place at least every six months and even more frequently when the shackles are used in severe operating conditions.

Shackles should be inspected to ensure that:

- all markings are legible;

- the body and pin are both identifiable as being of the same size, type and make;

- the threads of the pin and the body are undamaged;

- for a safety bolt type shackle is used with the split cotter pin;

- the body and the pin are not distorted or unduly worn;

- the body and pin are free from nicks, gouges, cracks and corrosion;

- shackles are not heat treated as this may affect their Working Load Limit;

- the shackle is not modified, repaired or reshaped by welding, heating, machining or bending as this will affect the Working Load Limit;

Remove the shackle from service if:

- all markings are not clearly legible;

- body and pin can not be identified as being from same size, type and make;

- the threads of the pin and/or body are damaged;

- for a safety bolt type shackle the split cotter pin is missing;

- the body and/or pin is distorted or unduly worn, the maximum allowable wear is 10% of the original dimension;

- the body and/or pin is not free from nicks, gouges, cracks or corrosion;

- the shackle has been exposed to any heat treatment;

- the shackle is modified, repaired or reshaped by welding, heating, machining or bending;

- t is expected that before the next periodical inspection any of the inspection criteria above will not be passed;

FAQ-Reference: PI-06-01. Rev: 0.

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

Please find the user manual here.

It is required that shackles are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure. Inspection should take place at least every six months and even more frequently when the shackles are used in severe operating conditions.

Shackles should be inspected to ensure that:

- all markings are legible;

- the body and pin are both identifiable as being of the same size, type and make;

- the threads of the pin and the body are undamaged;

- for a safety bolt type shackle is used with the split cotter pin;

- the body and the pin are not distorted or unduly worn;

- the body and pin are free from nicks, gouges, cracks and corrosion;

- shackles are not heat treated as this may affect their Working Load Limit;

- the shackle is not modified, repaired or reshaped by welding, heating, machining or bending as this will affect the Working Load Limit;

Remove the shackle from service if:

- all markings are not clearly legible;

- body and pin can not be identified as being from same size, type and make;

- the threads of the pin and/or body are damaged;

- for a safety bolt type shackle the split cotter pin is missing;

- the body and/or pin is distorted or unduly worn, the maximum allowable wear is 10% of the original dimension;

- the body and/or pin is not free from nicks, gouges, cracks or corrosion;

- the shackle has been exposed to any heat treatment;

- the shackle is modified, repaired or reshaped by welding, heating, machining or bending;

- t is expected that before the next periodical inspection any of the inspection criteria above will not be passed;

FAQ-Reference: PI-06-01. Rev: 0.

Please find the answer in this document.

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

Green Pin® shackles are known for their robust quality and versatility, are differentiated across various attributes which suit specific needs in different industries, including construction, maritime, and heavy lifting. They differ in grade, certificate, crown width, end fitting, number of safeties and special features. To discover all Green Pin shackles, visit the shackles category page here.

High load capacity bow shackle with safety bolt and fixed nut

Highlights

Saves on cost of wire/synthethic rope due to less wear

Saves on cost of wire/synthethic rope due to less wear

Triple safety (split pin, safety bolt, fixed nut)

Triple safety (split pin, safety bolt, fixed nut)

Top choice when the load is dynamic or exposed to extreme vibrations

Top choice when the load is dynamic or exposed to extreme vibrations

Galvanization assures long-term durability

Galvanization assures long-term durability

Shackles of 75T and higher include a Lloyd's proofload test certificate

Shackles of 75T and higher include a Lloyd's proofload test certificate

Description

The Green Pin® Sling Shackle FN is a high load capacity, bow shackle with a safety bolt and a fixed nut. The Sling Shackle FN is an excellent choice for heavy lifting projects due to the shape of the shackle crown. Compared to the standard Green Pin® Heavy Duty Shackles, Sling Shackles have an increased bow radius to improve your sling#s resistance to wear and tear and enable you to use a lighter wire rope to lift the same heavy load. This means that by using the Green Pin® Sling Shackle FN you save on wire rope costs (the Green Pin® Power Sling shackle offers even bigger savings however). Moreover, because of its triple safety (split pin, safety bolt and fixed nut) the shackle is the top choice among Sling shackles when the load is dynamic or exposed to extreme vibrations. The fixed nut of the Green Pin® Sling Shackle FN is drilled through both the shackle nut and pin and is firmly attached to the pin head with bolts and Nord-Lock® washers. Of course, galvanization of the Green Pin® Sling Shackle FN ensures long-term durability. A wide range of certifications is also available: sling shackles of 75 tons and higher include a Lloyd's proofload test certificate for example. The Green Pin® Sling Shackle FN is available in a range with a working load limit from 7 up to 150 tons.

Product details

- ProductcodeP-6013

- Materialbow and pin alloy steel, Grade 8, quenched and tempered

- Safety factorMBL equals 5 x WLL

- Finishshackle bow painted silver, pin painted green (7 up to 55 ton shackles are hot dipped galvanized)

- Temp. range-40°C up to +200°C

- Certification 2.1 2.2 3.1 MTCb LROS MPIb USb CE

Green Pin® Sling Shackle FN

Green Pin® Sling Shackle FN

| Article code | working load limit | Weight shackle pin |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Torque | Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0007FN | 7 | 0,99 | 22 | 22 | 46 | 19 | 32 | 96 | 64 | 153 | 115 | 110 | 19 | 41 | M6 | 45 | 9,2 | 1.97 |

| SLGPF0012FN | 12,5 | 1,82 | 28 | 28 | 61 | 25 | 44 | 120 | 82 | 197 | 151 | 146 | 24 | 54 | M8 | 50 | 22 | 4.27 |

| SLGPF0018FN | 18 | 2,35 | 35 | 35 | 69 | 30 | 54 | 148 | 102 | 239 | 171 | 180 | 29 | 64 | M10 | 65 | 43 | 6.85 |

| SLGPF0030FN | 30 | 4,23 | 40 | 42 | 90 | 35 | 69 | 165 | 126 | 279 | 207 | 200 | 34 | 79 | M6 | 75 | 9,2 | 12.5 |

| SLGPF0040FN | 40 | 4,32 | 55 | 51 | 109 | 45 | 84 | 199 | 140 | 331 | 252 | 235 | 38 | 97 | M8 | 90 | 22 | 20.3 |

| SLGPF0055FN | 55 | 4,6 | 60 | 57 | 115 | 55 | 90 | 240 | 160 | 389 | 294 | 270 | 45 | 100 | M10 | 100 | 43 | 30.4 |

| SLGPF0075FN | 75 | 11,39 | 68 | 70 | 126 | 54 | 110 | 290 | 185 | 473 | 317 | 317 | 40 | 120 | M12 | 120 | 75 | 45 |

| SLGPF0125FN | 125 | 18,59 | 85 | 80 | 156 | 85 | 137 | 366 | 220 | 583 | 413 | 390 | 40 | 150 | M12 | 130 | 75 | 92 |

| SLGPF0150FN | 150 | 27,25 | 94 | 95 | 181 | 89 | 147 | 391 | 253 | 648 | 445 | 449 | 50 | 170 | M12 | 140 | 75 | 140 |

Green Pin® Sling Shackle FN

Green Pin® Sling Shackle FN

| Article code | working load limit | Weight shackle pin |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Torque | Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0007FN | 7 | 2,18 | 7/8 | 7/8 | 1 13/16 | 3/4 | 1 9/32 | 3 25/32 | 2 17/32 | 6 | 4 17/32 | 4 5/16 | 3/4 | 1 5/8 | M6 | 1 3/4 | 9,2 | 4.34 |

| SLGPF0012FN | 12,5 | 4 | 1 1/8 | 1 1/8 | 2 3/8 | 1 | 1 3/4 | 4 23/32 | 3 1/4 | 7 3/4 | 5 15/16 | 5 3/4 | 15/16 | 2 1/8 | M8 | 2 | 22 | 9.42 |

| SLGPF0018FN | 18 | 5,18 | 1 3/8 | 1 3/8 | 2 23/32 | 1 3/16 | 2 1/8 | 5 13/16 | 4 1/32 | 9 13/32 | 6 23/32 | 7 3/32 | 1 5/32 | 2 17/32 | M10 | 2 1/2 | 43 | 15.1 |

| SLGPF0030FN | 30 | 9,33 | 1 9/16 | 1 21/32 | 3 17/32 | 1 3/8 | 2 23/32 | 6 1/2 | 4 31/32 | 10 31/32 | 8 5/32 | 7 7/8 | 1 11/32 | 3 1/8 | M6 | 2 15/16 | 9,2 | 27.5 |

| SLGPF0040FN | 40 | 9,52 | 2 5/32 | 2 | 4 9/32 | 1 25/32 | 3 5/16 | 7 27/32 | 5 1/2 | 13 1/32 | 9 29/32 | 9 1/4 | 1 1/2 | 3 13/16 | M8 | 3 17/32 | 22 | 44.7 |

| SLGPF0055FN | 55 | 10,14 | 2 3/8 | 2 1/4 | 4 17/32 | 2 5/32 | 3 17/32 | 9 7/16 | 6 5/16 | 15 5/16 | 11 9/16 | 10 5/8 | 1 25/32 | 3 15/16 | M10 | 3 15/16 | 43 | 67.1 |

| SLGPF0075FN | 75 | 25,11 | 2 11/16 | 2 3/4 | 4 31/32 | 2 1/8 | 4 11/32 | 11 13/32 | 7 9/32 | 18 5/8 | 12 15/32 | 12 15/32 | 1 9/16 | 4 23/32 | M12 | 4 23/32 | 75 | 99.2 |

| SLGPF0125FN | 125 | 40,98 | 3 11/32 | 3 5/32 | 6 5/32 | 3 11/32 | 5 13/32 | 14 13/32 | 8 21/32 | 22 15/16 | 16 1/4 | 15 11/32 | 1 9/16 | 5 29/32 | M12 | 5 1/8 | 75 | 203 |

| SLGPF0150FN | 150 | 60,08 | 3 11/16 | 3 3/4 | 7 1/8 | 3 1/2 | 5 25/32 | 15 13/32 | 9 31/32 | 25 1/2 | 17 17/32 | 17 11/16 | 1 31/32 | 6 11/16 | M12 | 5 1/2 | 75 | 309 |

Green Pin® Sling Shackle FN

Green Pin® Sling Shackle FN