Green Pin® Rotating Hoist Ring

Grade 8 rotating hoist ring

- Reliable Green Pin® quality and support

- Superior stock availability of 99%

The Green Pin® Rotating Hoist Ring is a grade 8 rotating hoist ring. The hoist ring can rotate 360° and pivot 180°. It has ISO metric threads as standard. Other special threads such as UNC are also available. The cylindric head of the screw prevents jamming during rotation of the hoist ring. The WLL indicated hereunder are given in the worst conditions of use, i.e. 90°. It is necessary to check the free moving of the pivoting shackle. The minimum safety factor is 5:1. The Green Pin® Rotating Hoist Ring is available in a range with a working load limit from 0.4 t. up to 12.5 t.

More-

ProductcodeADA

-

Materialalloy steel, Grade 8, quenched and tempered

-

Safety factorMBL equals 5 x WLL

-

Finishpainted white

-

Temp. range-40°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- MTCa

- MPIb

- CE

-

NoteWLL indicated hereunder are given in the worst conditions of use, i.e. 90°

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

Torque

(nm)

|

Torque

(nm)

|

diameter thread

(mm)

A

|

diameter thread

(mm)

A

|

width inside

(mm)

B

|

width inside (inch)

B

|

length inside (inch)

C

|

length inside

(mm)

C

|

diameter

(mm)

D

|

diameter (inch)

D

|

length (inch)

E

|

length

(mm)

E

|

thickness base (inch)

F

|

thickness base

(mm)

F

|

width outside (inch)

G

|

width outside

(mm)

G

|

diameter base (inch)

H

|

diameter base

(mm)

H

|

diameter base (inch)

I

|

diameter base

(mm)

I

|

length inside (inch)

J

|

length inside

(mm)

J

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPADA08 | 0,4 | 6,5 | 8 | 36 | 42 | 12 | 18 | 35 | 69 | 34 | 35 | 43 | 0.43 | ||||||||||||||

| GPADA08 | 0,4 | 6,5 | 8 | 1 13/32 | 1 21/32 | 15/32 | 23/32 | 1 3/8 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 0.95 | ||||||||||||||

| GPADA10 | 0,7 | 13 | 10 | 36 | 40 | 12 | 18 | 37 | 69 | 34 | 35 | 43 | 0.44 | ||||||||||||||

| GPADA10 | 0,7 | 13 | 10 | 1 13/32 | 1 9/16 | 15/32 | 23/32 | 1 15/32 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 0.97 | ||||||||||||||

| GPADA12 | 1 | 22 | 12 | 36 | 38 | 12 | 23 | 39 | 69 | 34 | 35 | 43 | 0.46 | ||||||||||||||

| GPADA12 | 1 | 22 | 12 | 1 13/32 | 1 1/2 | 15/32 | 29/32 | 1 17/32 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 1.01 | ||||||||||||||

| GPADA14 | 1,3 | 35 | 14 | 36 | 36 | 12 | 23 | 41 | 69 | 34 | 35 | 43 | 0.47 | ||||||||||||||

| GPADA14 | 1,3 | 35 | 14 | 1 13/32 | 1 13/32 | 15/32 | 29/32 | 1 5/8 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 1.04 | ||||||||||||||

| GPADA16 | 1,6 | 55 | 16 | 36 | 43 | 12 | 28 | 43 | 69 | 34 | 35 | 52 | 0.52 | ||||||||||||||

| GPADA16 | 1,6 | 55 | 16 | 1 13/32 | 1 11/16 | 15/32 | 1 3/32 | 1 11/16 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.15 | ||||||||||||||

| GPADA18 | 2 | 80 | 18 | 36 | 41 | 12 | 28 | 45 | 69 | 34 | 35 | 52 | 0.54 | ||||||||||||||

| GPADA18 | 2 | 80 | 18 | 1 13/32 | 1 5/8 | 15/32 | 1 3/32 | 1 25/32 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.19 | ||||||||||||||

| GPADA20 | 2,5 | 110 | 20 | 36 | 39 | 12 | 33 | 47 | 69 | 34 | 35 | 52 | 0.59 | ||||||||||||||

| GPADA20 | 2,5 | 110 | 20 | 1 13/32 | 1 17/32 | 15/32 | 1 5/16 | 1 27/32 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.30 | ||||||||||||||

| GPADA22 | 3 | 150 | 22 | 53 | 57 | 19 | 32 | 70 | 104 | 49 | 52 | 71 | 1.88 | ||||||||||||||

| GPADA22 | 3 | 150 | 22 | 2 3/32 | 2 1/4 | 3/4 | 1 1/4 | 2 3/4 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.15 | ||||||||||||||

| GPADA24 | 4 | 190 | 24 | 53 | 56 | 19 | 37 | 72 | 104 | 49 | 52 | 71 | 1.93 | ||||||||||||||

| GPADA24 | 4 | 190 | 24 | 2 3/32 | 2 7/32 | 3/4 | 1 15/32 | 2 27/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.26 | ||||||||||||||

| GPADA27 | 5 | 280 | 27 | 53 | 63 | 19 | 45 | 64 | 104 | 49 | 52 | 71 | 1.96 | ||||||||||||||

| GPADA27 | 5 | 280 | 27 | 2 3/32 | 2 15/32 | 3/4 | 1 25/32 | 2 17/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.32 | ||||||||||||||

| GPADA30 | 6,3 | 380 | 30 | 53 | 63 | 19 | 45 | 64 | 104 | 49 | 52 | 71 | 2.03 | ||||||||||||||

| GPADA30 | 6,3 | 380 | 30 | 2 3/32 | 2 15/32 | 3/4 | 1 25/32 | 2 17/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.48 | ||||||||||||||

| GPADA33 | 7 | 520 | 33 | 73 | 93 | 30 | 54 | 83 | 149 | 68 | 72 | 98 | 5.28 | ||||||||||||||

| GPADA33 | 7 | 520 | 33 | 2 7/8 | 3 21/32 | 1 3/16 | 2 1/8 | 3 9/32 | 5 7/8 | 2 11/16 | 2 27/32 | 3 27/32 | 11.6 | ||||||||||||||

| GPADA36 | 10 | 600 | 36 | 73 | 93 | 30 | 54 | 83 | 149 | 68 | 72 | 98 | 5.35 | ||||||||||||||

| GPADA36 | 10 | 600 | 36 | 2 7/8 | 3 21/32 | 1 3/16 | 2 1/8 | 3 9/32 | 5 7/8 | 2 11/16 | 2 27/32 | 3 27/32 | 11.8 | ||||||||||||||

| GPADA39 | 10 | 870 | 39 | 73 | 93 | 30 | 63 | 83 | 149 | 68 | 72 | 98 | 5.45 | ||||||||||||||

| GPADA39 | 10 | 870 | 39 | 2 7/8 | 3 21/32 | 1 3/16 | 2 15/32 | 3 9/32 | 5 7/8 | 2 11/16 | 3 27/32 | 3 27/32 | 12.0 | ||||||||||||||

| GPADA42 | 12,5 | 1000 | 42 | 71 | 87 | 30 | 63 | 84 | 146 | 68 | 77 | 98 | 5.56 | ||||||||||||||

| GPADA42 | 12,5 | 1000 | 42 | 2 25/32 | 3 7/16 | 1 3/16 | 2 15/32 | 3 5/16 | 5 3/4 | 2 11/16 | 3 1/32 | 3 27/32 | 12.3 |

Frequently Asked Questions

Please find the user manual here.

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

FAQ-Reference PI-07-02 Rev. B

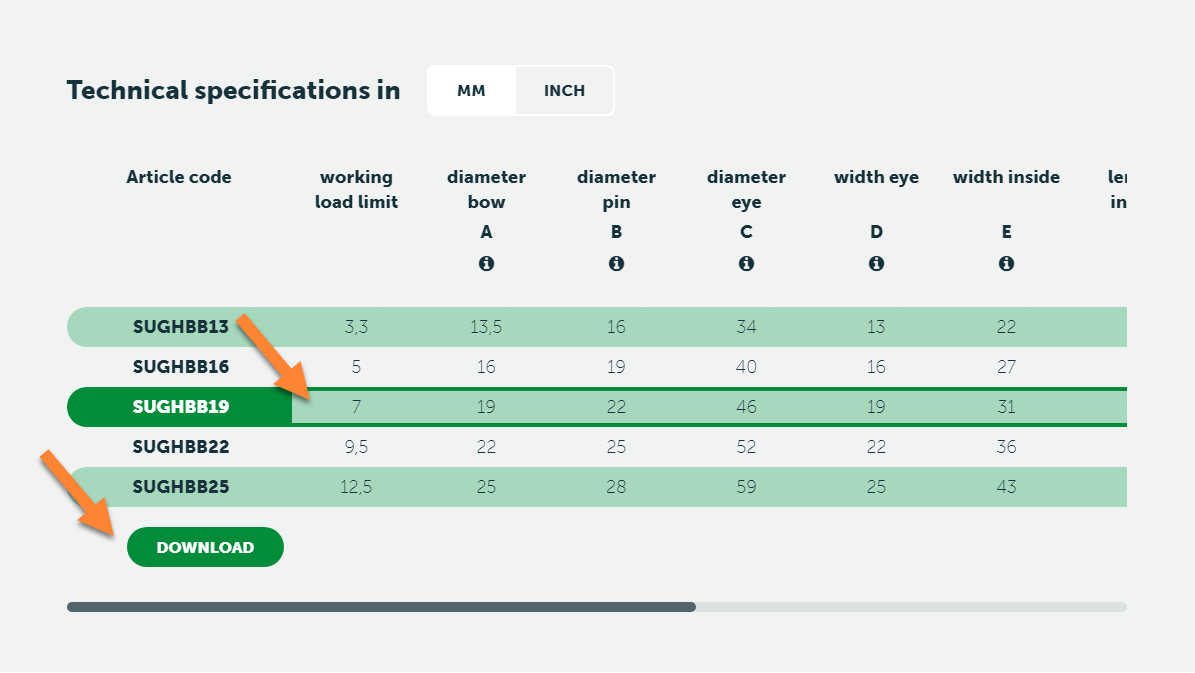

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

Grade 8 rotating hoist ring

Highlights

Reliable Green Pin® quality and support

Reliable Green Pin® quality and support

Superior stock availability of 99%

Superior stock availability of 99%

Description

The Green Pin® Rotating Hoist Ring is a grade 8 rotating hoist ring. The hoist ring can rotate 360° and pivot 180°. It has ISO metric threads as standard. Other special threads such as UNC are also available. The cylindric head of the screw prevents jamming during rotation of the hoist ring. The WLL indicated hereunder are given in the worst conditions of use, i.e. 90°. It is necessary to check the free moving of the pivoting shackle. The minimum safety factor is 5:1. The Green Pin® Rotating Hoist Ring is available in a range with a working load limit from 0.4 t. up to 12.5 t.

Product details

- ProductcodeADA

- Materialalloy steel, Grade 8, quenched and tempered

- Safety factorMBL equals 5 x WLL

- Finishpainted white

- Temp. range-40°C up to +200°C

- Certification 2.1 2.2 3.1 MTCa MPIb CE

- NoteWLL indicated hereunder are given in the worst conditions of use, i.e. 90°

Green Pin® Rotating Hoist Ring

Green Pin® Rotating Hoist Ring

| Article code | working load limit | Torque |

|

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPADA08 | 0,4 | 6,5 | 8 | 36 | 42 | 12 | 18 | 35 | 69 | 34 | 35 | 43 | 0.43 |

| GPADA10 | 0,7 | 13 | 10 | 36 | 40 | 12 | 18 | 37 | 69 | 34 | 35 | 43 | 0.44 |

| GPADA12 | 1 | 22 | 12 | 36 | 38 | 12 | 23 | 39 | 69 | 34 | 35 | 43 | 0.46 |

| GPADA14 | 1,3 | 35 | 14 | 36 | 36 | 12 | 23 | 41 | 69 | 34 | 35 | 43 | 0.47 |

| GPADA16 | 1,6 | 55 | 16 | 36 | 43 | 12 | 28 | 43 | 69 | 34 | 35 | 52 | 0.52 |

| GPADA18 | 2 | 80 | 18 | 36 | 41 | 12 | 28 | 45 | 69 | 34 | 35 | 52 | 0.54 |

| GPADA20 | 2,5 | 110 | 20 | 36 | 39 | 12 | 33 | 47 | 69 | 34 | 35 | 52 | 0.59 |

| GPADA22 | 3 | 150 | 22 | 53 | 57 | 19 | 32 | 70 | 104 | 49 | 52 | 71 | 1.88 |

| GPADA24 | 4 | 190 | 24 | 53 | 56 | 19 | 37 | 72 | 104 | 49 | 52 | 71 | 1.93 |

| GPADA27 | 5 | 280 | 27 | 53 | 63 | 19 | 45 | 64 | 104 | 49 | 52 | 71 | 1.96 |

| GPADA30 | 6,3 | 380 | 30 | 53 | 63 | 19 | 45 | 64 | 104 | 49 | 52 | 71 | 2.03 |

| GPADA33 | 7 | 520 | 33 | 73 | 93 | 30 | 54 | 83 | 149 | 68 | 72 | 98 | 5.28 |

Green Pin® Rotating Hoist Ring

Green Pin® Rotating Hoist Ring

| Article code | working load limit | Torque |

|

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPADA36 | 10 | 600 | 36 | 73 | 93 | 30 | 54 | 83 | 149 | 68 | 72 | 98 | 5.35 |

| GPADA39 | 10 | 870 | 39 | 73 | 93 | 30 | 63 | 83 | 149 | 68 | 72 | 98 | 5.45 |

| GPADA42 | 12,5 | 1000 | 42 | 71 | 87 | 30 | 63 | 84 | 146 | 68 | 77 | 98 | 5.56 |

Green Pin® Rotating Hoist Ring

Green Pin® Rotating Hoist Ring

| Article code | working load limit | Torque |

|

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPADA08 | 0,4 | 6,5 | 8 | 1 13/32 | 1 21/32 | 15/32 | 23/32 | 1 3/8 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 0.95 |

| GPADA10 | 0,7 | 13 | 10 | 1 13/32 | 1 9/16 | 15/32 | 23/32 | 1 15/32 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 0.97 |

| GPADA12 | 1 | 22 | 12 | 1 13/32 | 1 1/2 | 15/32 | 29/32 | 1 17/32 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 1.01 |

| GPADA14 | 1,3 | 35 | 14 | 1 13/32 | 1 13/32 | 15/32 | 29/32 | 1 5/8 | 2 23/32 | 1 11/32 | 1 3/8 | 1 11/16 | 1.04 |

| GPADA16 | 1,6 | 55 | 16 | 1 13/32 | 1 11/16 | 15/32 | 1 3/32 | 1 11/16 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.15 |

| GPADA18 | 2 | 80 | 18 | 1 13/32 | 1 5/8 | 15/32 | 1 3/32 | 1 25/32 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.19 |

| GPADA20 | 2,5 | 110 | 20 | 1 13/32 | 1 17/32 | 15/32 | 1 5/16 | 1 27/32 | 2 23/32 | 1 11/32 | 1 3/8 | 2 1/16 | 1.30 |

| GPADA22 | 3 | 150 | 22 | 2 3/32 | 2 1/4 | 3/4 | 1 1/4 | 2 3/4 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.15 |

| GPADA24 | 4 | 190 | 24 | 2 3/32 | 2 7/32 | 3/4 | 1 15/32 | 2 27/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.26 |

| GPADA27 | 5 | 280 | 27 | 2 3/32 | 2 15/32 | 3/4 | 1 25/32 | 2 17/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.32 |

| GPADA30 | 6,3 | 380 | 30 | 2 3/32 | 2 15/32 | 3/4 | 1 25/32 | 2 17/32 | 4 3/32 | 1 15/16 | 2 1/16 | 2 25/32 | 4.48 |

| GPADA33 | 7 | 520 | 33 | 2 7/8 | 3 21/32 | 1 3/16 | 2 1/8 | 3 9/32 | 5 7/8 | 2 11/16 | 2 27/32 | 3 27/32 | 11.6 |

Green Pin® Rotating Hoist Ring

Green Pin® Rotating Hoist Ring

| Article code | working load limit | Torque |

|

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPADA36 | 10 | 600 | 36 | 2 7/8 | 3 21/32 | 1 3/16 | 2 1/8 | 3 9/32 | 5 7/8 | 2 11/16 | 2 27/32 | 3 27/32 | 11.8 |

| GPADA39 | 10 | 870 | 39 | 2 7/8 | 3 21/32 | 1 3/16 | 2 15/32 | 3 9/32 | 5 7/8 | 2 11/16 | 3 27/32 | 3 27/32 | 12.0 |

| GPADA42 | 12,5 | 1000 | 42 | 2 25/32 | 3 7/16 | 1 3/16 | 2 15/32 | 3 5/16 | 5 3/4 | 2 11/16 | 3 1/32 | 3 27/32 | 12.3 |

Green Pin® Rotating Hoist Ring

Green Pin® Rotating Hoist Ring