Green Pin® Locking Clamp ROV Sling Shackle

Release ROV Sling shackle (grade 8) with locking clamp

- Powerful locking system ensures load is not released unintentionally

- Locking system is easy to handle for the ROV pilot

- Saves on cost of wire/synthethic rope due to less wear

- Designed for under water use in harsh conditions

- Excellent choice for heavy lifting projects

The Green Pin® Locking Clamp ROV Sling Shackle is perfect for release operations with remotely operated vehicles (ROV). The grade 8 shackle has been specially developed for sub-sea applications and is easy to handle for the ROV pilot.The Locking Clamp ROV Sling Shackle is an excellent choice due to the shape of the shackle crown. Compared to the standard Green Pin® Shackles, Sling Shackles have an increased bow radius to improve your sling's resistance to wear and tear and enable you to use a lighter rope to lift the same heavy load. This means that by using the Green Pin® Locking Clamp ROV Sling Shackle you can save on rope costs.The ROV Sling Shackle has a powerful locking system that ensures that the load will not be released before you want it to. The white coating optimizes visibility underwater and ensures its long-term durability. The Green Pin® Locking Clamp ROV Sling Shackle is available in a range with a working load limit from 12.5 up to 300 tons.

More-

ProductcodeP-6065

-

Materialbow and pin alloy steel, Grade 8, quenched and tempered

-

Safety factorMBL equals 5 x WLL

-

Finishshackle bow painted white, pin painted green

-

Temp. range-40°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- MTCb

- CE IIA

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

Net weight

(kg)

|

Net weight

(lbs)

|

diameter body

(mm)

A

|

diameter body (inch)

A

|

diameter pin

(mm)

B

|

diameter pin (inch)

B

|

diameter eye (inch)

C

|

diameter eye

(mm)

C

|

width eye

(mm)

D

|

width eye (inch)

D

|

width inside (inch)

E

|

width inside

(mm)

E

|

length inside (inch)

F

|

length inside

(mm)

F

|

width bow

(mm)

G

|

width bow (inch)

G

|

length (inch)

H

|

length

(mm)

H

|

length bolt

(mm)

I

|

length bolt (inch)

I

|

width

(mm)

J

|

width (inch)

J

|

width locking clamp (inch)

K

|

width locking clamp

(mm)

K

|

bearing surface (inch)

L

|

bearing surface

(mm)

L

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0012ROVRLLC | 12,5 | 4.27 | 28 | 28 | 61 | 25 | 44 | 121 | 82 | 197 | 143 | 146 | 31 | 54 | 4.27 | ||||||||||||||||

| SLGPF0012ROVRLLC | 12,5 | 9.42 | 1 1/8 | 1 1/8 | 2 3/8 | 1 | 1 3/4 | 4 3/4 | 3 1/4 | 7 3/4 | 5 5/8 | 5 3/4 | 1 7/32 | 2 1/8 | 9.42 | ||||||||||||||||

| SLGPF0018ROVRLLC | 18 | 6.85 | 35 | 35 | 69 | 30 | 54 | 148 | 102 | 239 | 184 | 180 | 31 | 64 | 6.85 | ||||||||||||||||

| SLGPF0018ROVRLLC | 18 | 15.1 | 1 3/8 | 1 3/8 | 2 23/32 | 1 3/16 | 2 1/8 | 5 13/16 | 4 1/32 | 9 13/32 | 7 1/4 | 7 3/32 | 1 7/32 | 2 17/32 | 15.1 | ||||||||||||||||

| SLGPF0030ROVRLLC | 30 | 12.5 | 40 | 42 | 90 | 35 | 69 | 165 | 126 | 279 | 210 | 200 | 40 | 79 | 12.5 | ||||||||||||||||

| SLGPF0030ROVRLLC | 30 | 27.5 | 1 9/16 | 1 21/32 | 3 17/32 | 1 3/8 | 2 23/32 | 6 1/2 | 4 31/32 | 10 31/32 | 8 9/32 | 7 7/8 | 1 9/16 | 3 1/8 | 27.5 | ||||||||||||||||

| SLGPF0040ROVRLLC | 40 | 20.3 | 55 | 51 | 109 | 45 | 84 | 199 | 140 | 331 | 256 | 235 | 40 | 97 | 20.3 | ||||||||||||||||

| SLGPF0040ROVRLLC | 40 | 44.7 | 2 5/32 | 2 | 4 9/32 | 1 25/32 | 3 5/16 | 7 27/32 | 5 1/2 | 13 1/32 | 10 3/32 | 9 1/4 | 1 9/16 | 3 13/16 | 44.7 | ||||||||||||||||

| SLGPF0055ROVRLLC | 55 | 30.4 | 60 | 57 | 115 | 55 | 90 | 240 | 160 | 389 | 289 | 270 | 40 | 100 | 30.4 | ||||||||||||||||

| SLGPF0055ROVRLLC | 55 | 67.1 | 2 3/8 | 2 1/4 | 4 17/32 | 2 5/32 | 3 17/32 | 9 7/16 | 6 5/16 | 15 5/16 | 11 3/8 | 10 5/8 | 1 9/16 | 3 15/16 | 67.1 | ||||||||||||||||

| SLGPF0075ROVRLLC | 75 | 45.0 | 68 | 70 | 125 | 54 | 110 | 290 | 185 | 473 | 317 | 317 | 40 | 120 | 45.0 | ||||||||||||||||

| SLGPF0075ROVRLLC | 75 | 99.2 | 2 11/16 | 2 3/4 | 4 29/32 | 2 1/8 | 4 11/32 | 11 13/32 | 7 9/32 | 18 5/8 | 12 15/32 | 12 15/32 | 1 9/16 | 4 23/32 | 99.2 | ||||||||||||||||

| SLGPF0125ROVRLLC | 125 | 92.0 | 85 | 80 | 154 | 85 | 137 | 366 | 220 | 583 | 413 | 390 | 40 | 150 | 92.0 | ||||||||||||||||

| SLGPF0125ROVRLLC | 125 | 203 | 3 11/32 | 3 5/32 | 6 1/16 | 3 11/32 | 5 13/32 | 14 13/32 | 8 21/32 | 22 15/16 | 16 1/4 | 15 11/32 | 1 9/16 | 5 29/32 | 203 | ||||||||||||||||

| SLGPF0150ROVRLLC | 150 | 140 | 94 | 95 | 179 | 89 | 147 | 391 | 253 | 645 | 445 | 434 | 55 | 170 | 140 | ||||||||||||||||

| SLGPF0150ROVRLLC | 150 | 309 | 3 11/16 | 3 3/4 | 7 1/16 | 3 1/2 | 5 25/32 | 15 13/32 | 9 31/32 | 25 13/32 | 17 17/32 | 17 3/32 | 2 5/32 | 6 11/16 | 309 | ||||||||||||||||

| SLGPF0200ROVRLLC | 200 | 205 | 110 | 105 | 199 | 100 | 158 | 481 | 280 | 759 | 480 | 482 | 55 | 205 | 205 | ||||||||||||||||

| SLGPF0200ROVRLLC | 200 | 452 | 4 11/32 | 4 1/8 | 7 27/32 | 3 15/16 | 6 7/32 | 18 15/16 | 11 1/32 | 29 7/8 | 18 29/32 | 18 31/32 | 2 5/32 | 8 1/16 | 452 | ||||||||||||||||

| SLGPF0250ROVRLLC | 250 | 264 | 126 | 120 | 227 | 110 | 179 | 542 | 300 | 859 | 523 | 530 | 55 | 240 | 264 | ||||||||||||||||

| SLGPF0250ROVRLLC | 250 | 582 | 4 31/32 | 4 23/32 | 8 15/16 | 4 11/32 | 7 1/16 | 21 11/32 | 11 13/16 | 33 13/16 | 20 19/32 | 20 7/8 | 2 5/32 | 9 7/16 | 582 | ||||||||||||||||

| SLGPF0300ROVRLLC | 300 | 360 | 135 | 134 | 245 | 122 | 195 | 601 | 350 | 947 | 563 | 620 | 55 | 265 | 360 | ||||||||||||||||

| SLGPF0300ROVRLLC | 300 | 794 | 5 5/16 | 5 9/32 | 9 21/32 | 4 13/16 | 7 11/16 | 23 21/32 | 13 25/32 | 37 9/32 | 22 5/32 | 24 13/32 | 2 5/32 | 10 7/16 | 794 |

Do you have questions about this product? Don't hesitate to contact us.

Product video

Frequently Asked Questions

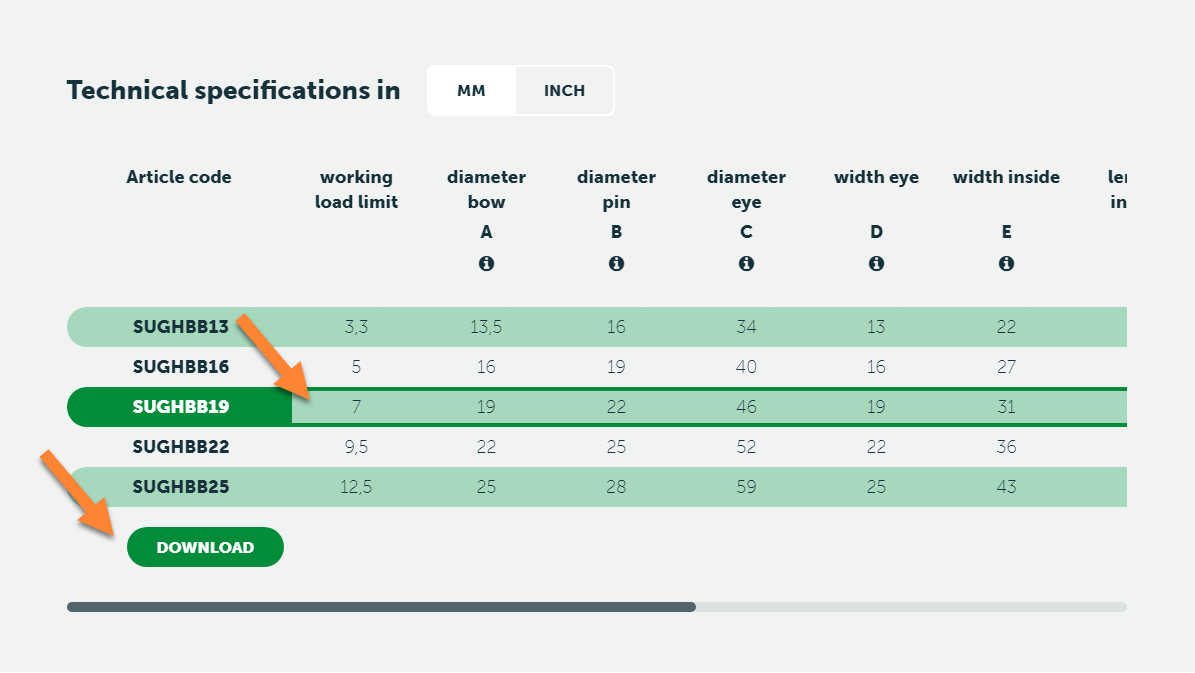

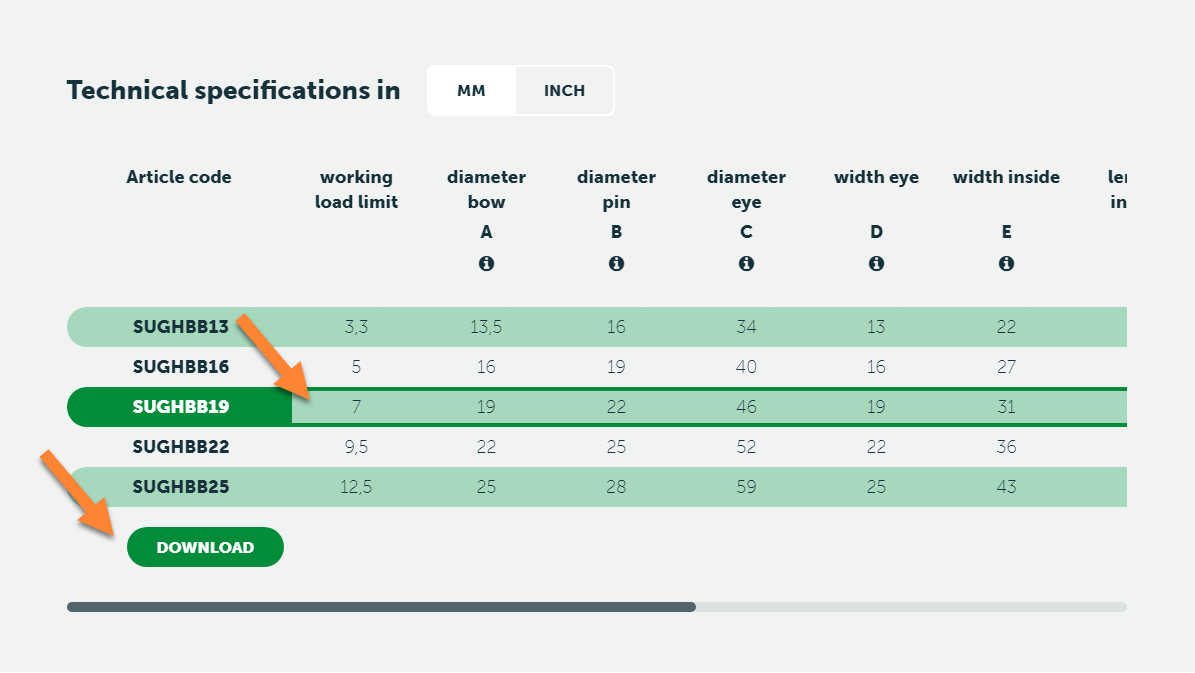

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

Please find the user manual here.

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

Green Pin® shackles are known for their robust quality and versatility, are differentiated across various attributes which suit specific needs in different industries, including construction, maritime, and heavy lifting. They differ in grade, certificate, crown width, end fitting, number of safeties and special features. To discover all Green Pin shackles, visit the shackles category page here.

Release ROV Sling shackle (grade 8) with locking clamp

Highlights

Powerful locking system ensures load is not released unintentionally

Powerful locking system ensures load is not released unintentionally

Locking system is easy to handle for the ROV pilot

Locking system is easy to handle for the ROV pilot

Saves on cost of wire/synthethic rope due to less wear

Saves on cost of wire/synthethic rope due to less wear

Designed for under water use in harsh conditions

Designed for under water use in harsh conditions

Excellent choice for heavy lifting projects

Excellent choice for heavy lifting projects

Description

The Green Pin® Locking Clamp ROV Sling Shackle is perfect for release operations with remotely operated vehicles (ROV). The grade 8 shackle has been specially developed for sub-sea applications and is easy to handle for the ROV pilot.The Locking Clamp ROV Sling Shackle is an excellent choice due to the shape of the shackle crown. Compared to the standard Green Pin® Shackles, Sling Shackles have an increased bow radius to improve your sling's resistance to wear and tear and enable you to use a lighter rope to lift the same heavy load. This means that by using the Green Pin® Locking Clamp ROV Sling Shackle you can save on rope costs.The ROV Sling Shackle has a powerful locking system that ensures that the load will not be released before you want it to. The white coating optimizes visibility underwater and ensures its long-term durability. The Green Pin® Locking Clamp ROV Sling Shackle is available in a range with a working load limit from 12.5 up to 300 tons.

Product details

- ProductcodeP-6065

- Materialbow and pin alloy steel, Grade 8, quenched and tempered

- Safety factorMBL equals 5 x WLL

- Finishshackle bow painted white, pin painted green

- Temp. range-40°C up to +200°C

- Certification 2.1 2.2 3.1 MTCb CE IIA

Green Pin® Locking Clamp ROV Sling Shackle

Green Pin® Locking Clamp ROV Sling Shackle

| Article code | working load limit | Net weight |

|

|

|

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0012ROVRLLC | 12,5 | 4.27 | 28 | 28 | 61 | 25 | 44 | 121 | 82 | 197 | 143 | 146 | 31 | 54 | 4.27 |

| SLGPF0018ROVRLLC | 18 | 6.85 | 35 | 35 | 69 | 30 | 54 | 148 | 102 | 239 | 184 | 180 | 31 | 64 | 6.85 |

| SLGPF0030ROVRLLC | 30 | 12.5 | 40 | 42 | 90 | 35 | 69 | 165 | 126 | 279 | 210 | 200 | 40 | 79 | 12.5 |

| SLGPF0040ROVRLLC | 40 | 20.3 | 55 | 51 | 109 | 45 | 84 | 199 | 140 | 331 | 256 | 235 | 40 | 97 | 20.3 |

| SLGPF0055ROVRLLC | 55 | 30.4 | 60 | 57 | 115 | 55 | 90 | 240 | 160 | 389 | 289 | 270 | 40 | 100 | 30.4 |

| SLGPF0075ROVRLLC | 75 | 45.0 | 68 | 70 | 125 | 54 | 110 | 290 | 185 | 473 | 317 | 317 | 40 | 120 | 45.0 |

| SLGPF0125ROVRLLC | 125 | 92.0 | 85 | 80 | 154 | 85 | 137 | 366 | 220 | 583 | 413 | 390 | 40 | 150 | 92.0 |

| SLGPF0150ROVRLLC | 150 | 140 | 94 | 95 | 179 | 89 | 147 | 391 | 253 | 645 | 445 | 434 | 55 | 170 | 140 |

| SLGPF0200ROVRLLC | 200 | 205 | 110 | 105 | 199 | 100 | 158 | 481 | 280 | 759 | 480 | 482 | 55 | 205 | 205 |

| SLGPF0250ROVRLLC | 250 | 264 | 126 | 120 | 227 | 110 | 179 | 542 | 300 | 859 | 523 | 530 | 55 | 240 | 264 |

| SLGPF0300ROVRLLC | 300 | 360 | 135 | 134 | 245 | 122 | 195 | 601 | 350 | 947 | 563 | 620 | 55 | 265 | 360 |

Green Pin® Locking Clamp ROV Sling Shackle

Green Pin® Locking Clamp ROV Sling Shackle

| Article code | working load limit | Net weight |

|

|

|

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLGPF0012ROVRLLC | 12,5 | 9.42 | 1 1/8 | 1 1/8 | 2 3/8 | 1 | 1 3/4 | 4 3/4 | 3 1/4 | 7 3/4 | 5 5/8 | 5 3/4 | 1 7/32 | 2 1/8 | 9.42 |

| SLGPF0018ROVRLLC | 18 | 15.1 | 1 3/8 | 1 3/8 | 2 23/32 | 1 3/16 | 2 1/8 | 5 13/16 | 4 1/32 | 9 13/32 | 7 1/4 | 7 3/32 | 1 7/32 | 2 17/32 | 15.1 |

| SLGPF0030ROVRLLC | 30 | 27.5 | 1 9/16 | 1 21/32 | 3 17/32 | 1 3/8 | 2 23/32 | 6 1/2 | 4 31/32 | 10 31/32 | 8 9/32 | 7 7/8 | 1 9/16 | 3 1/8 | 27.5 |

| SLGPF0040ROVRLLC | 40 | 44.7 | 2 5/32 | 2 | 4 9/32 | 1 25/32 | 3 5/16 | 7 27/32 | 5 1/2 | 13 1/32 | 10 3/32 | 9 1/4 | 1 9/16 | 3 13/16 | 44.7 |

| SLGPF0055ROVRLLC | 55 | 67.1 | 2 3/8 | 2 1/4 | 4 17/32 | 2 5/32 | 3 17/32 | 9 7/16 | 6 5/16 | 15 5/16 | 11 3/8 | 10 5/8 | 1 9/16 | 3 15/16 | 67.1 |

| SLGPF0075ROVRLLC | 75 | 99.2 | 2 11/16 | 2 3/4 | 4 29/32 | 2 1/8 | 4 11/32 | 11 13/32 | 7 9/32 | 18 5/8 | 12 15/32 | 12 15/32 | 1 9/16 | 4 23/32 | 99.2 |

| SLGPF0125ROVRLLC | 125 | 203 | 3 11/32 | 3 5/32 | 6 1/16 | 3 11/32 | 5 13/32 | 14 13/32 | 8 21/32 | 22 15/16 | 16 1/4 | 15 11/32 | 1 9/16 | 5 29/32 | 203 |

| SLGPF0150ROVRLLC | 150 | 309 | 3 11/16 | 3 3/4 | 7 1/16 | 3 1/2 | 5 25/32 | 15 13/32 | 9 31/32 | 25 13/32 | 17 17/32 | 17 3/32 | 2 5/32 | 6 11/16 | 309 |

| SLGPF0200ROVRLLC | 200 | 452 | 4 11/32 | 4 1/8 | 7 27/32 | 3 15/16 | 6 7/32 | 18 15/16 | 11 1/32 | 29 7/8 | 18 29/32 | 18 31/32 | 2 5/32 | 8 1/16 | 452 |

| SLGPF0250ROVRLLC | 250 | 582 | 4 31/32 | 4 23/32 | 8 15/16 | 4 11/32 | 7 1/16 | 21 11/32 | 11 13/16 | 33 13/16 | 20 19/32 | 20 7/8 | 2 5/32 | 9 7/16 | 582 |

| SLGPF0300ROVRLLC | 300 | 794 | 5 5/16 | 5 9/32 | 9 21/32 | 4 13/16 | 7 11/16 | 23 21/32 | 13 25/32 | 37 9/32 | 22 5/32 | 24 13/32 | 2 5/32 | 10 7/16 | 794 |

Green Pin® Locking Clamp ROV Sling Shackle

Green Pin® Locking Clamp ROV Sling Shackle