Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket

- Highlights

- High tensile steel

- Galvanization assures long-term durability

- Superior stock availability of 99%

- Reliable Green Pin® quality and support

- Can be used in combination with the Socket Lock Socketing Resin

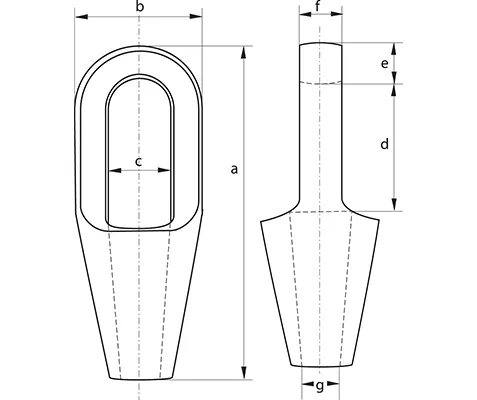

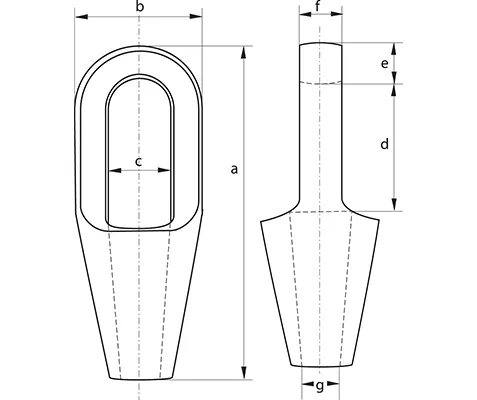

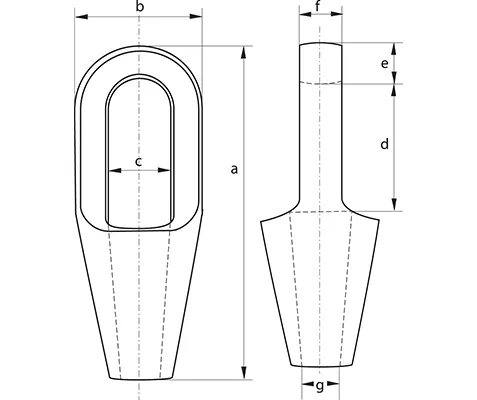

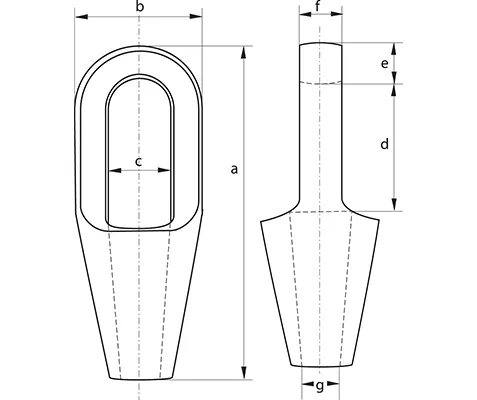

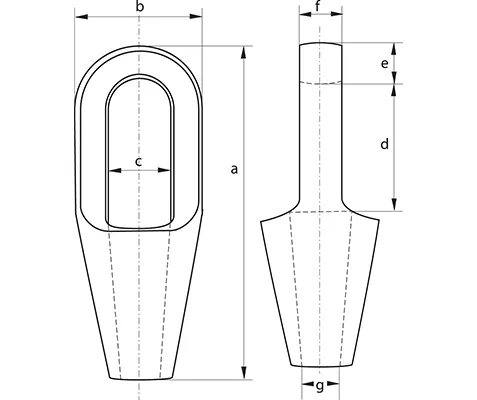

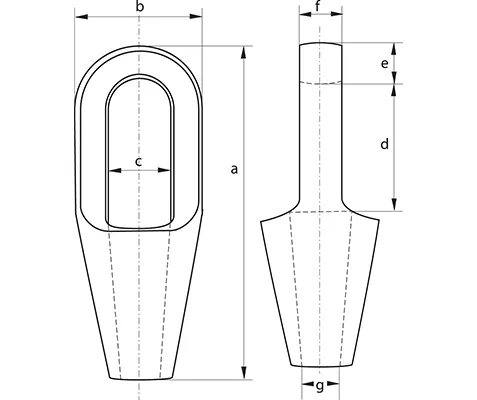

The Green Pin® Closed Spelter Socket is made from high tensile steel. Its long-term durability is assured due to galvanization. The Green Pin® Closed Spelter Socket is available for a diameter wire rope of 6-7 up to 120-130 mm and can be used in combination with the Socket Lock Socketing Resin.

More-

ProductcodeG-6411

-

Materialhigh tensile steel

-

Finishhot dipped galvanized

-

Temp. range-40°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- CE

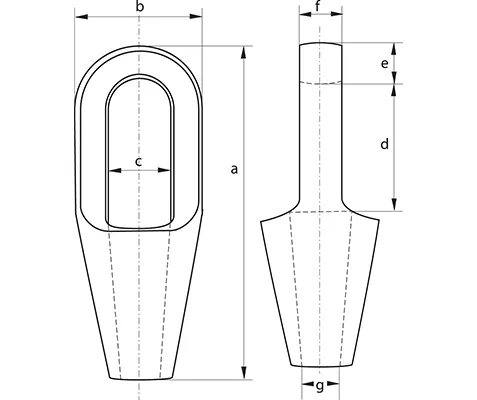

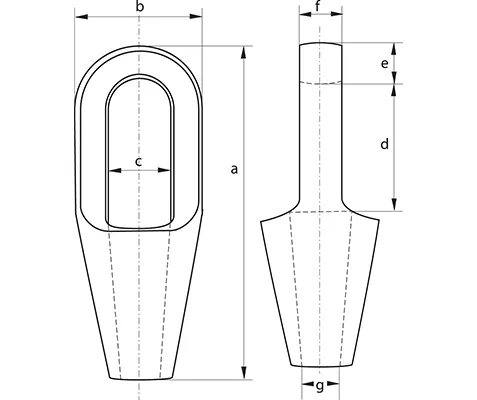

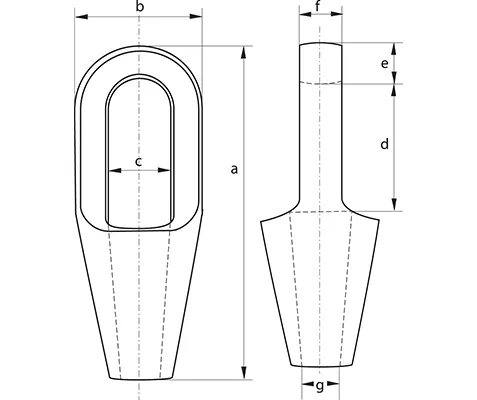

| Article code |

Number

(inch)

|

Number

(mm)

|

minimum breaking load

(ton)

|

minimum breaking load

(ton)

|

diameter wire rope

(mm)

|

diameter wire rope (inch)

|

length (inch)

A

|

length

(mm)

A

|

width (inch)

B

|

width

(mm)

B

|

width inside bow (inch)

C

|

width inside bow

(mm)

C

|

length inside bow (inch)

D

|

length inside bow

(mm)

D

|

thickness bow (inch)

E

|

thickness bow

(mm)

E

|

thickness bow (inch)

F

|

thickness bow

(mm)

F

|

opening (inch)

G

|

opening

(mm)

G

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SKGCS007 | 296 | 8 | 6 - 7 | 101 | 37 | 22 | 40 | 11 | 13 | 9 | 0.26 | ||||||||||||

| SKGCS007 | 296 | 8 | 1/4 | 3 31/32 | 1 15/32 | 7/8 | 1 19/16 | 7/16 | 1/2 | 11/32 | 0.56 | ||||||||||||

| SKGCS010 | 297 | 12 | 8 - 10 | 119 | 43 | 25 | 48 | 14 | 17,5 | 12 | 0.50 | ||||||||||||

| SKGCS010 | 297 | 12 | 3/8 | 4 11/16 | 1 11/16 | 31/32 | 1 7/8 | 9/16 | 11/16 | 15/32 | 1.10 | ||||||||||||

| SKGCS013 | 298 | 20 | 11 - 13 | 140 | 52 | 30 | 58 | 18 | 23,5 | 15 | 0.72 | ||||||||||||

| SKGCS013 | 298 | 20 | 7/16 - 1/2 | 5 1/2 | 2 1/16 | 1 3/16 | 2 9/32 | 23/32 | 15/16 | 19/32 | 1.59 | ||||||||||||

| SKGCS016 | 299 | 25 | 14 - 16 | 162 | 68 | 37 | 66 | 21 | 26 | 17,5 | 1.47 | ||||||||||||

| SKGCS016 | 299 | 25 | 9/16 - 5/8 | 6 3/8 | 2 11/16 | 1 15/32 | 2 19/32 | 13/16 | 1 1/32 | 11/16 | 3.24 | ||||||||||||

| SKGCS018 | 200 | 45 | 18 - 19 | 194 | 76 | 42 | 78 | 27 | 32 | 21,5 | 2.24 | ||||||||||||

| SKGCS018 | 200 | 45 | 3/4 | 7 5/8 | 3 | 1 21/32 | 3 1/16 | 1 1/16 | 1 1/4 | 27/32 | 4.94 | ||||||||||||

| SKGCS022 | 201 | 70 | 20 - 22 | 224 | 92 | 47 | 90 | 33 | 38 | 24 | 4.20 | ||||||||||||

| SKGCS022 | 201 | 70 | 7/8 | 8 13/16 | 3 5/8 | 1 27/32 | 3 17/32 | 1 5/16 | 1 1/2 | 15/16 | 9.27 | ||||||||||||

| SKGCS025 | 204 | 85 | 23 - 26 | 253 | 104 | 57 | 103 | 36 | 44 | 28 | 6.03 | ||||||||||||

| SKGCS025 | 204 | 85 | 1 | 9 31/32 | 4 3/32 | 2 1/4 | 4 1/16 | 1 13/32 | 1 23/32 | 1 3/32 | 13.3 | ||||||||||||

| SKGCS028 | 207 | 105 | 27 - 30 | 282 | 114 | 63 | 116 | 39 | 51 | 32 | 7.85 | ||||||||||||

| SKGCS028 | 207 | 105 | 1 1/8 | 11 3/32 | 4 1/2 | 2 15/32 | 4 9/16 | 1 17/32 | 2 | 1 1/4 | 17.3 | ||||||||||||

| SKGCS032 | 212 | 136 | 31 - 36 | 312 | 127 | 70 | 130 | 43 | 57 | 38 | 10.8 | ||||||||||||

| SKGCS032 | 212 | 136 | 1 1/4 - 1 3/8 | 12 9/32 | 5 | 2 3/4 | 5 1/8 | 1 11/16 | 2 1/4 | 1 1/2 | 23.7 | ||||||||||||

| SKGCS038 | 215 | 150 | 37 - 39 | 358 | 136 | 79 | 155 | 51 | 63 | 41 | 13.6 | ||||||||||||

| SKGCS038 | 215 | 150 | 1 1/2 | 14 3/32 | 5 11/32 | 3 1/8 | 6 3/32 | 2 | 2 15/32 | 1 5/8 | 30.0 | ||||||||||||

| SKGCS042 | 217 | 170 | 40 - 42 | 390 | 146 | 83 | 171 | 54 | 70 | 44 | 17.0 | ||||||||||||

| SKGCS042 | 217 | 170 | 1 5/8 | 15 11/32 | 5 3/4 | 3 9/32 | 6 23/32 | 2 1/8 | 2 3/4 | 1 23/32 | 37.5 | ||||||||||||

| SKGCS045 | 219 | 225 | 43 - 48 | 443 | 171 | 93 | 198 | 55 | 76 | 51 | 26 | ||||||||||||

| SKGCS045 | 219 | 225 | 1 3/4 - 1 7/8 | 17 7/16 | 6 23/32 | 3 21/32 | 7 25/32 | 2 5/32 | 3 | 2 | 57.3 | ||||||||||||

| SKGCS054 | 222 | 280 | 49 - 54 | 502 | 193 | 100 | 224 | 62 | 82 | 57 | 37.5 | ||||||||||||

| SKGCS054 | 222 | 280 | 2 - 2 1/8 | 19 3/4 | 7 19/32 | 3 15/16 | 8 13/16 | 2 7/16 | 3 7/32 | 2 1/4 | 82.7 | ||||||||||||

| SKGCS057 | 224 | 360 | 55 - 60 | 548 | 216 | 112 | 247 | 73 | 92 | 63 | 54.5 | ||||||||||||

| SKGCS057 | 224 | 360 | 2 1/4 - 2 3/8 | 21 9/16 | 8 1/2 | 4 13/32 | 9 23/32 | 2 7/8 | 3 5/8 | 2 15/32 | 120 | ||||||||||||

| SKGCS064 | 226 | 425 | 61 - 68 | 597 | 241 | 140 | 270 | 79 | 102 | 73 | 69.5 | ||||||||||||

| SKGCS064 | 226 | 425 | 2 1/2 - 2 5/8 | 23 1/2 | 9 1/2 | 5 1/2 | 10 5/8 | 3 1/8 | 4 1/32 | 2 7/8 | 153 | ||||||||||||

| SKGCS073 | 227 | 460 | 69 - 75 | 644 | 273 | 159 | 286 | 79 | 124 | 79 | 100 | ||||||||||||

| SKGCS073 | 227 | 460 | 2 3/4 - 2 7/8 | 25 11/32 | 10 3/4 | 6 1/4 | 11 1/4 | 3 1/8 | 4 7/8 | 3 1/8 | 221 | ||||||||||||

| SKGCS075 | 228 | 560 | 76 - 80 | 686 | 292 | 171 | 298 | 83 | 133 | 86 | 121 | ||||||||||||

| SKGCS075 | 228 | 560 | 3 - 3 1/8 | 27 | 11 1/2 | 6 23/32 | 11 23/32 | 3 9/32 | 5 1/4 | 3 3/8 | 266 | ||||||||||||

| SKGCS085 | 229 | 625 | 81 - 86 | 743 | 311 | 184 | 311 | 102 | 146 | 92 | 156 | ||||||||||||

| SKGCS085 | 229 | 625 | 3 1/4 - 3 3/8 | 29 1/4 | 12 1/4 | 7 1/4 | 12 1/4 | 4 1/32 | 5 3/4 | 3 5/8 | 344 | ||||||||||||

| SKGCS090 | 230 | 720 | 87 - 93 | 788 | 330 | 197 | 330 | 102 | 159 | 99 | 181 | ||||||||||||

| SKGCS090 | 230 | 720 | 3 1/2 - 3 5/8 | 31 1/32 | 13 | 7 3/4 | 13 | 4 1/32 | 6 1/4 | 3 29/32 | 399 | ||||||||||||

| SKGCS100 | 231 | 875 | 94 - 102 | 845 | 362 | 216 | 356 | 108 | 178 | 108 | 210 | ||||||||||||

| SKGCS100 | 231 | 875 | 3 3/4 - 4 | 33 9/32 | 14 1/4 | 8 1/2 | 14 1/32 | 4 1/4 | 7 | 4 1/4 | 463 | ||||||||||||

| SKGCS110 | 233 | 1200 | 108 - 115 | 1000 | 405 | 235 | 425 | 125 | 190 | 125 | 334 | ||||||||||||

| SKGCS110 | 233 | 1200 | 4 1/4 - 4 1/2 | 39 3/8 | 15 15/16 | 9 1/4 | 16 23/32 | 4 29/32 | 7 15/32 | 4 29/32 | 736 | ||||||||||||

| SKGCS120 | 240 | 1300 | 120 - 130 | 1150 | 450 | 260 | 525 | 125 | 200 | 143 | 500 | ||||||||||||

| SKGCS120 | 240 | 1300 | 4 3/4 - 5 | 45 9/32 | 17 23/32 | 10 1/4 | 20 21/32 | 4 29/32 | 7 7/8 | 5 5/8 | 1103 |

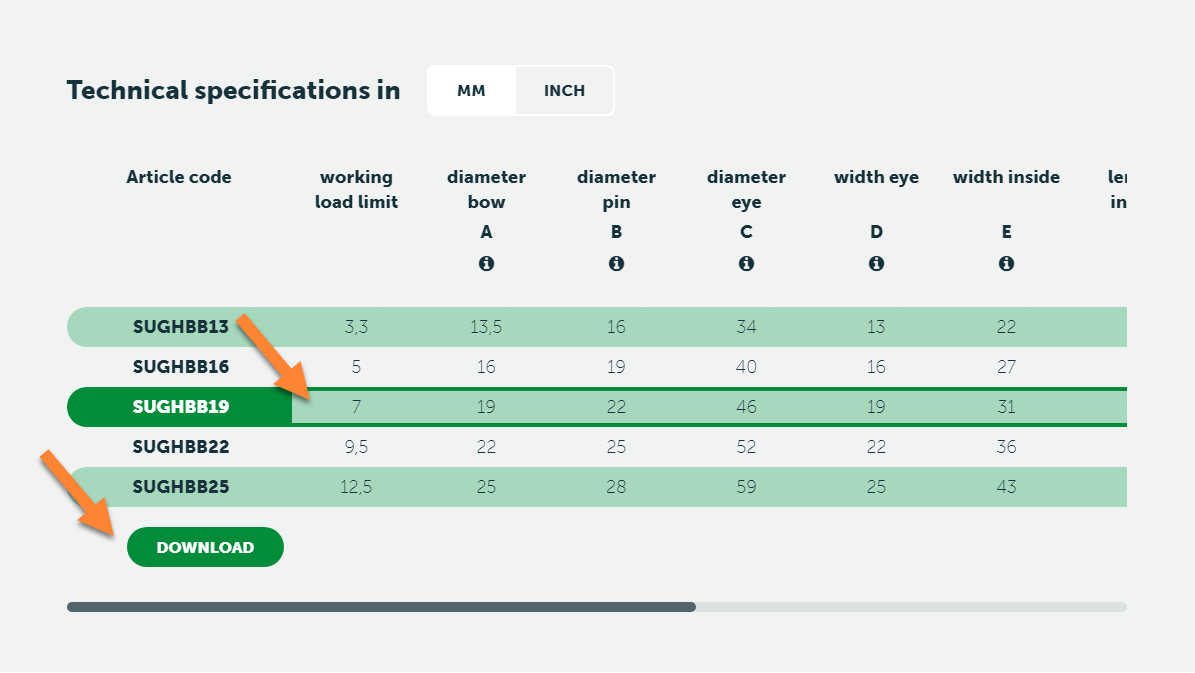

Frequently Asked Questions

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

FAQ-Reference PI-07-02 Rev. B

You can find the socket brochure here!

Green Pin® Closed Spelter Socket

Highlights

High tensile steel

High tensile steel

Galvanization assures long-term durability

Galvanization assures long-term durability

Superior stock availability of 99%

Superior stock availability of 99%

Reliable Green Pin® quality and support

Reliable Green Pin® quality and support

Can be used in combination with the Socket Lock Socketing Resin

Can be used in combination with the Socket Lock Socketing Resin

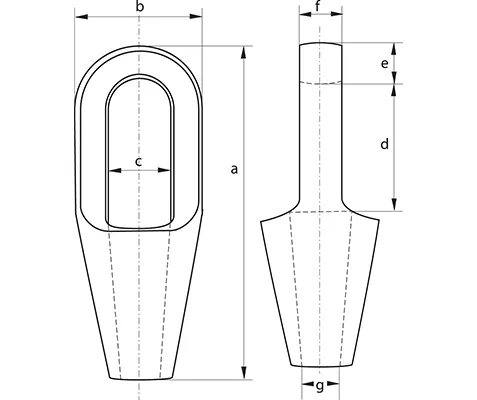

Description

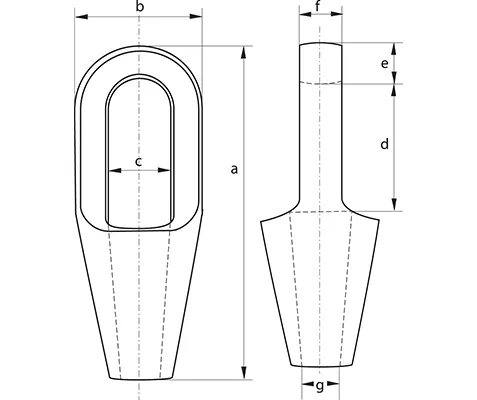

The Green Pin® Closed Spelter Socket is made from high tensile steel. Its long-term durability is assured due to galvanization. The Green Pin® Closed Spelter Socket is available for a diameter wire rope of 6-7 up to 120-130 mm and can be used in combination with the Socket Lock Socketing Resin.

Product details

- ProductcodeG-6411

- Materialhigh tensile steel

- Finishhot dipped galvanized

- Certification 2.1 2.2 3.1 CE

Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket

| Article code | Number | minimum breaking load | diameter wire rope |

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SKGCS007 | 296 | 8 | 6 - 7 | 101 | 37 | 22 | 40 | 11 | 13 | 9 | 0.26 |

| SKGCS010 | 297 | 12 | 8 - 10 | 119 | 43 | 25 | 48 | 14 | 17,5 | 12 | 0.50 |

| SKGCS013 | 298 | 20 | 11 - 13 | 140 | 52 | 30 | 58 | 18 | 23,5 | 15 | 0.72 |

| SKGCS016 | 299 | 25 | 14 - 16 | 162 | 68 | 37 | 66 | 21 | 26 | 17,5 | 1.47 |

| SKGCS018 | 200 | 45 | 18 - 19 | 194 | 76 | 42 | 78 | 27 | 32 | 21,5 | 2.24 |

| SKGCS022 | 201 | 70 | 20 - 22 | 224 | 92 | 47 | 90 | 33 | 38 | 24 | 4.20 |

| SKGCS025 | 204 | 85 | 23 - 26 | 253 | 104 | 57 | 103 | 36 | 44 | 28 | 6.03 |

| SKGCS028 | 207 | 105 | 27 - 30 | 282 | 114 | 63 | 116 | 39 | 51 | 32 | 7.85 |

| SKGCS032 | 212 | 136 | 31 - 36 | 312 | 127 | 70 | 130 | 43 | 57 | 38 | 10.8 |

| SKGCS038 | 215 | 150 | 37 - 39 | 358 | 136 | 79 | 155 | 51 | 63 | 41 | 13.6 |

| SKGCS042 | 217 | 170 | 40 - 42 | 390 | 146 | 83 | 171 | 54 | 70 | 44 | 17.0 |

| SKGCS045 | 219 | 225 | 43 - 48 | 443 | 171 | 93 | 198 | 55 | 76 | 51 | 26 |

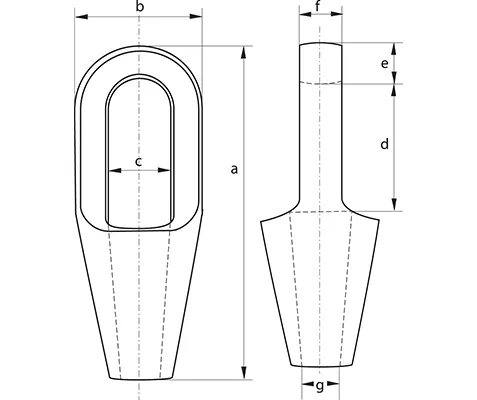

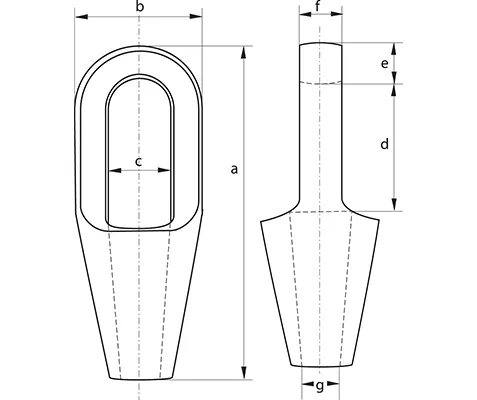

Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket

| Article code | Number | minimum breaking load | diameter wire rope |

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SKGCS054 | 222 | 280 | 49 - 54 | 502 | 193 | 100 | 224 | 62 | 82 | 57 | 37.5 |

| SKGCS057 | 224 | 360 | 55 - 60 | 548 | 216 | 112 | 247 | 73 | 92 | 63 | 54.5 |

| SKGCS064 | 226 | 425 | 61 - 68 | 597 | 241 | 140 | 270 | 79 | 102 | 73 | 69.5 |

| SKGCS073 | 227 | 460 | 69 - 75 | 644 | 273 | 159 | 286 | 79 | 124 | 79 | 100 |

| SKGCS075 | 228 | 560 | 76 - 80 | 686 | 292 | 171 | 298 | 83 | 133 | 86 | 121 |

| SKGCS085 | 229 | 625 | 81 - 86 | 743 | 311 | 184 | 311 | 102 | 146 | 92 | 156 |

| SKGCS090 | 230 | 720 | 87 - 93 | 788 | 330 | 197 | 330 | 102 | 159 | 99 | 181 |

| SKGCS100 | 231 | 875 | 94 - 102 | 845 | 362 | 216 | 356 | 108 | 178 | 108 | 210 |

| SKGCS110 | 233 | 1200 | 108 - 115 | 1000 | 405 | 235 | 425 | 125 | 190 | 125 | 334 |

| SKGCS120 | 240 | 1300 | 120 - 130 | 1150 | 450 | 260 | 525 | 125 | 200 | 143 | 500 |

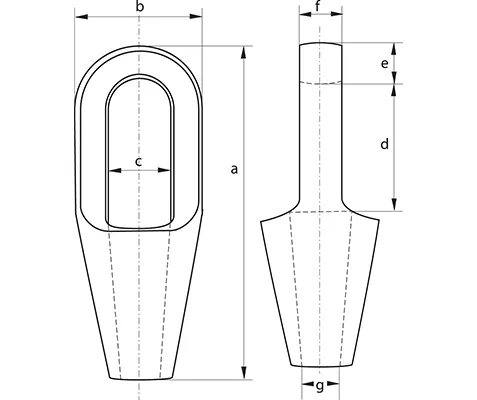

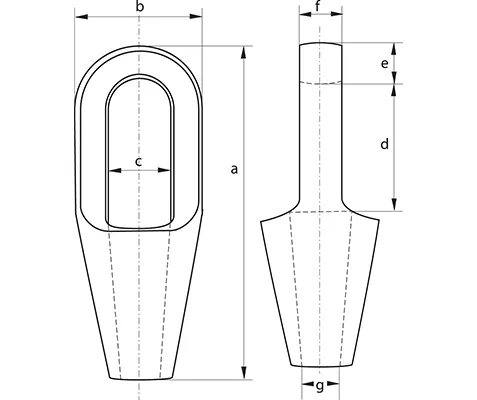

Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket

| Article code | Number | minimum breaking load | diameter wire rope (inch) |

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SKGCS007 | 296 | 8 | 1/4 | 3 31/32 | 1 15/32 | 7/8 | 1 19/16 | 7/16 | 1/2 | 11/32 | 0.56 |

| SKGCS010 | 297 | 12 | 3/8 | 4 11/16 | 1 11/16 | 31/32 | 1 7/8 | 9/16 | 11/16 | 15/32 | 1.10 |

| SKGCS013 | 298 | 20 | 7/16 - 1/2 | 5 1/2 | 2 1/16 | 1 3/16 | 2 9/32 | 23/32 | 15/16 | 19/32 | 1.59 |

| SKGCS016 | 299 | 25 | 9/16 - 5/8 | 6 3/8 | 2 11/16 | 1 15/32 | 2 19/32 | 13/16 | 1 1/32 | 11/16 | 3.24 |

| SKGCS018 | 200 | 45 | 3/4 | 7 5/8 | 3 | 1 21/32 | 3 1/16 | 1 1/16 | 1 1/4 | 27/32 | 4.94 |

| SKGCS022 | 201 | 70 | 7/8 | 8 13/16 | 3 5/8 | 1 27/32 | 3 17/32 | 1 5/16 | 1 1/2 | 15/16 | 9.27 |

| SKGCS025 | 204 | 85 | 1 | 9 31/32 | 4 3/32 | 2 1/4 | 4 1/16 | 1 13/32 | 1 23/32 | 1 3/32 | 13.3 |

| SKGCS028 | 207 | 105 | 1 1/8 | 11 3/32 | 4 1/2 | 2 15/32 | 4 9/16 | 1 17/32 | 2 | 1 1/4 | 17.3 |

| SKGCS032 | 212 | 136 | 1 1/4 - 1 3/8 | 12 9/32 | 5 | 2 3/4 | 5 1/8 | 1 11/16 | 2 1/4 | 1 1/2 | 23.7 |

| SKGCS038 | 215 | 150 | 1 1/2 | 14 3/32 | 5 11/32 | 3 1/8 | 6 3/32 | 2 | 2 15/32 | 1 5/8 | 30.0 |

| SKGCS042 | 217 | 170 | 1 5/8 | 15 11/32 | 5 3/4 | 3 9/32 | 6 23/32 | 2 1/8 | 2 3/4 | 1 23/32 | 37.5 |

| SKGCS045 | 219 | 225 | 1 3/4 - 1 7/8 | 17 7/16 | 6 23/32 | 3 21/32 | 7 25/32 | 2 5/32 | 3 | 2 | 57.3 |

Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket

| Article code | Number | minimum breaking load | diameter wire rope (inch) |

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SKGCS054 | 222 | 280 | 2 - 2 1/8 | 19 3/4 | 7 19/32 | 3 15/16 | 8 13/16 | 2 7/16 | 3 7/32 | 2 1/4 | 82.7 |

| SKGCS057 | 224 | 360 | 2 1/4 - 2 3/8 | 21 9/16 | 8 1/2 | 4 13/32 | 9 23/32 | 2 7/8 | 3 5/8 | 2 15/32 | 120 |

| SKGCS064 | 226 | 425 | 2 1/2 - 2 5/8 | 23 1/2 | 9 1/2 | 5 1/2 | 10 5/8 | 3 1/8 | 4 1/32 | 2 7/8 | 153 |

| SKGCS073 | 227 | 460 | 2 3/4 - 2 7/8 | 25 11/32 | 10 3/4 | 6 1/4 | 11 1/4 | 3 1/8 | 4 7/8 | 3 1/8 | 221 |

| SKGCS075 | 228 | 560 | 3 - 3 1/8 | 27 | 11 1/2 | 6 23/32 | 11 23/32 | 3 9/32 | 5 1/4 | 3 3/8 | 266 |

| SKGCS085 | 229 | 625 | 3 1/4 - 3 3/8 | 29 1/4 | 12 1/4 | 7 1/4 | 12 1/4 | 4 1/32 | 5 3/4 | 3 5/8 | 344 |

| SKGCS090 | 230 | 720 | 3 1/2 - 3 5/8 | 31 1/32 | 13 | 7 3/4 | 13 | 4 1/32 | 6 1/4 | 3 29/32 | 399 |

| SKGCS100 | 231 | 875 | 3 3/4 - 4 | 33 9/32 | 14 1/4 | 8 1/2 | 14 1/32 | 4 1/4 | 7 | 4 1/4 | 463 |

| SKGCS110 | 233 | 1200 | 4 1/4 - 4 1/2 | 39 3/8 | 15 15/16 | 9 1/4 | 16 23/32 | 4 29/32 | 7 15/32 | 4 29/32 | 736 |

| SKGCS120 | 240 | 1300 | 4 3/4 - 5 | 45 9/32 | 17 23/32 | 10 1/4 | 20 21/32 | 4 29/32 | 7 7/8 | 5 5/8 | 1103 |

Green Pin® Closed Spelter Socket

Green Pin® Closed Spelter Socket