Green Pin® Snatch Block HK

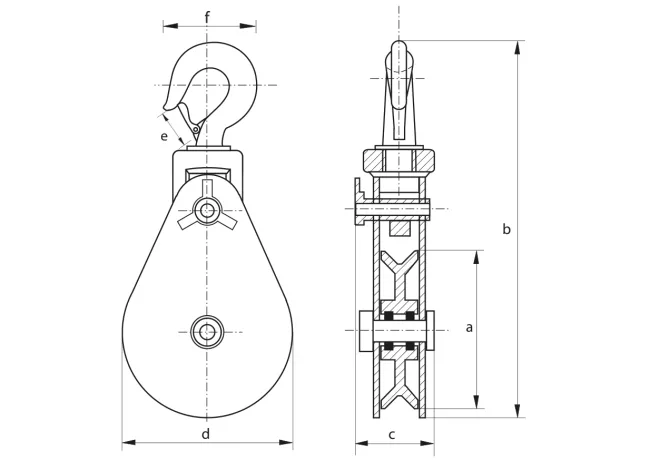

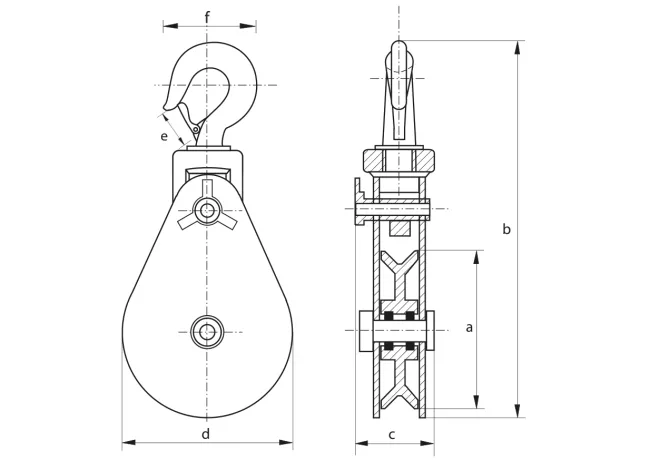

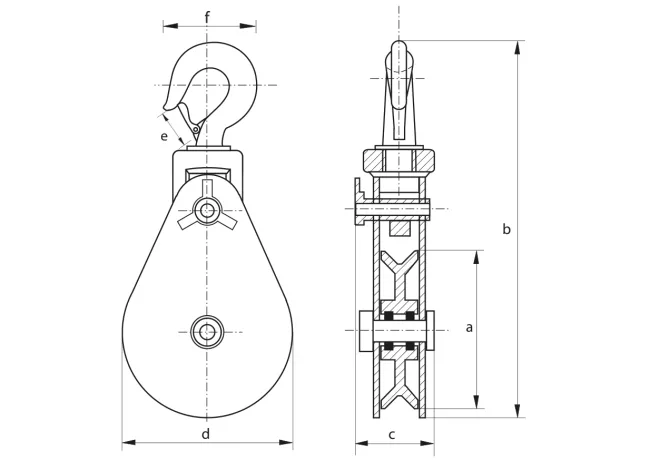

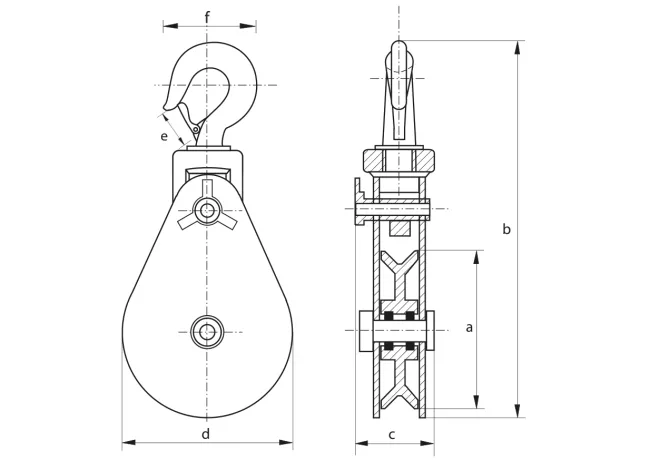

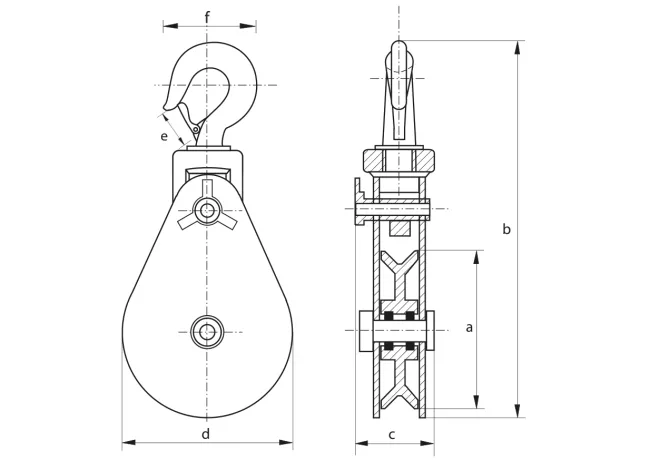

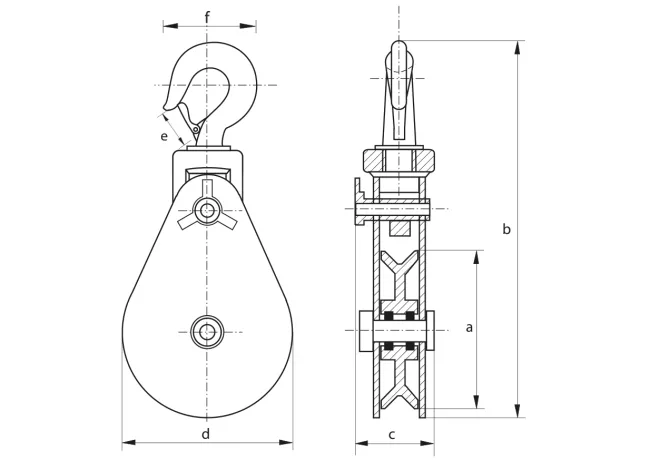

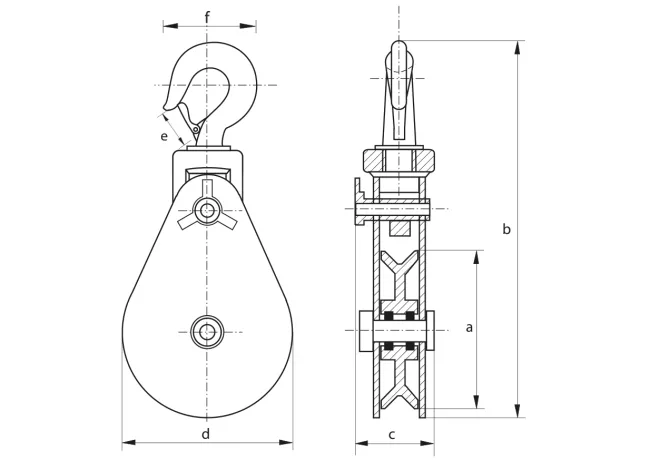

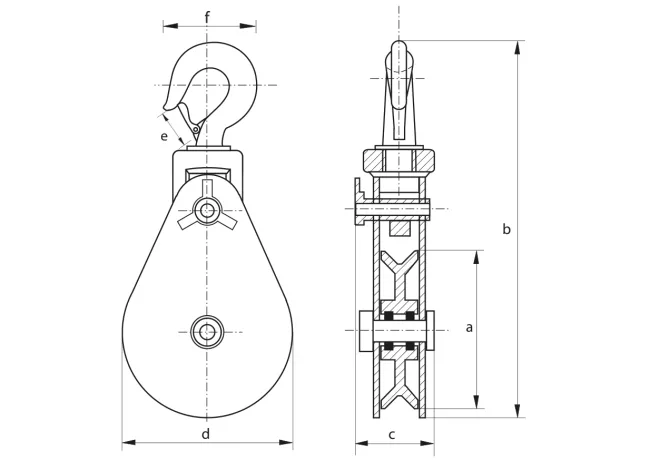

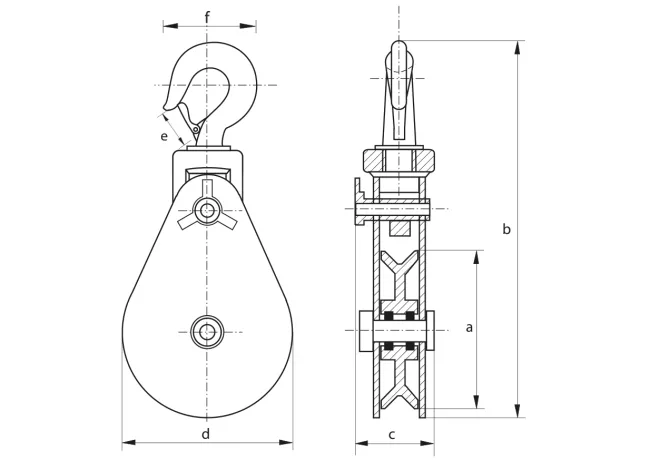

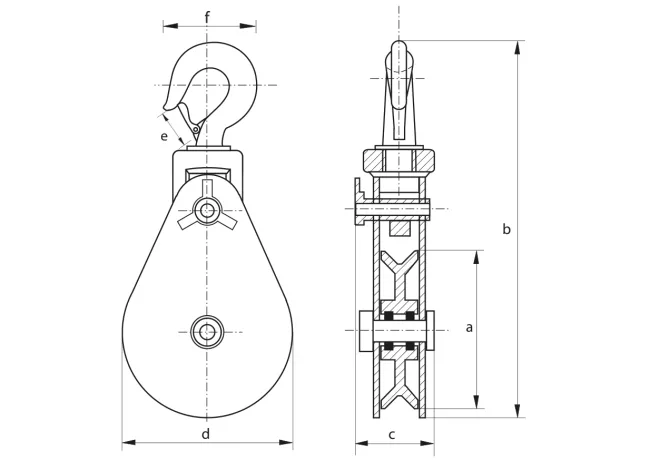

Snatch block type 601HK with Hook attached

- Highlights

- Smooth, uninterrupted pull due to conical roller bearings

- Coating assures long-term durability

- Lightweight

- Superior stock availability of 99%

- Reliable Green Pin® quality and support

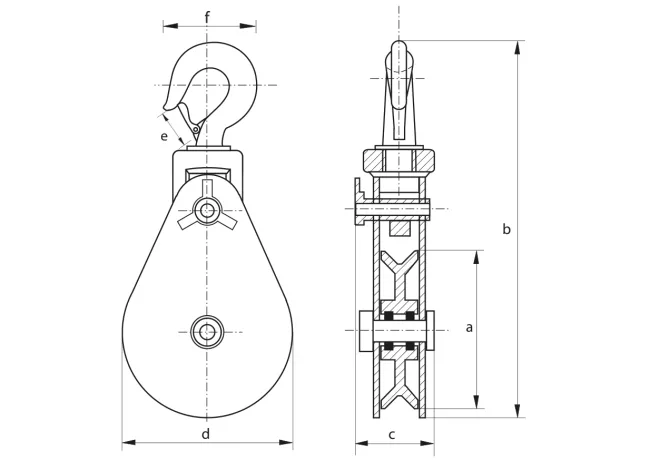

The Green Pin® Snatch Block HK is a light-weight snatch block type 601HK with a hook attached. The snatch block has a smooth, uninterrupted pull due to the conical roller bearings. The coating of the Green Pin® Snatch Block HK ensures long-term durability, even under harsh conditions. It is available in a range with a working load limit from 2 up to 15 ton.

More-

ProductcodeP-6952

-

Materialcarbon steel, fitted with conical roller bearings

-

Safety factorMBL equals 4 x WLL

-

Finishpainted

-

Certification

- 2.1

- 2.2

- MTCb

- CE

-

NoteWorking Load Limit is on the headfitting

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

diameter wire rope (inch)

|

diameter wire rope

(mm)

|

diameter outside sheave (inch)

A

|

diameter outside sheave

(mm)

A

|

length (inch)

B

|

length

(mm)

B

|

thickness (inch)

C

|

thickness

(mm)

C

|

width outside (inch)

D

|

width outside

(mm)

D

|

opening hook (inch)

E

|

opening hook

(mm)

E

|

width (inch)

F

|

width

(mm)

F

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH0302 | 2 | 7 - 9 | 75 | 290 | 87 | 82 | 28 | 108 | 3.68 | ||||||||||

| BKOFFSH0302 | 2 | 9/32 - 3/8 | 2 15/16 | 11 13/32 | 3 7/16 | 3 7/32 | 1 3/32 | 4 1/4 | 8.12 | ||||||||||

| BKOFFSH0404 | 4 | 10 - 12 | 115 | 358 | 89 | 120 | 43 | 125 | 6.00 | ||||||||||

| BKOFFSH0404 | 4 | 3/8 - 1/2 | 4 17/32 | 14 3/32 | 3 1/2 | 4 23/32 | 1 11/16 | 4 29/32 | 13.2 | ||||||||||

| BKOFFSH0604 | 4 | 12 - 14 | 150 | 412 | 89 | 160 | 40 | 125 | 8.50 | ||||||||||

| BKOFFSH0604 | 4 | 1/2 - 9/16 | 5 29/32 | 16 7/32 | 3 1/2 | 6 5/16 | 1 9/16 | 4 29/32 | 18.7 | ||||||||||

| BKOFFSH0608 | 8 | 20 - 22 | 150 | 502 | 119 | 160 | 48 | 165 | 11.8 | ||||||||||

| BKOFFSH0608 | 8 | 3/4 - 7/8 | 5 29/32 | 19 3/4 | 4 11/16 | 6 5/16 | 1 7/8 | 6 1/2 | 26.0 | ||||||||||

| BKOFFSH0612 | 12 | 20 - 22 | 150 | 616 | 119 | 160 | 70 | 236 | 20.5 | ||||||||||

| BKOFFSH0612 | 12 | 3/4 - 7/8 | 5 29/32 | 24 1/4 | 4 11/16 | 6 5/16 | 2 3/4 | 9 9/32 | 45.2 | ||||||||||

| BKOFFSH0615 | 15 | 24 - 26 | 150 | 626 | 138 | 160 | 70 | 236 | 23.4 | ||||||||||

| BKOFFSH0615 | 15 | 1 | 5 29/32 | 24 21/32 | 5 7/16 | 6 5/16 | 2 3/4 | 9 9/32 | 51.6 | ||||||||||

| BKOFFSH0804 | 4 | 10 - 12 | 200 | 473 | 91 | 210 | 40 | 125 | 8 | ||||||||||

| BKOFFSH0804 | 4 | 3/8 - 15/32 | 7 7/8 | 18 5/8 | 3 19/32 | 8 9/32 | 1 9/16 | 4 29/32 | 17.6 | ||||||||||

| BKOFFSH0808 | 8 | 20 - 22 | 200 | 551 | 119 | 210 | 48 | 165 | 20.4 | ||||||||||

| BKOFFSH0808 | 8 | 3/4 - 7/8 | 7 7/8 | 21 11/16 | 4 11/16 | 8 9/32 | 1 7/8 | 6 1/2 | 44.9 | ||||||||||

| BKOFFSH0812 | 12 | 20 - 22 | 200 | 641 | 129 | 210 | 70 | 236 | 30.0 | ||||||||||

| BKOFFSH0812 | 12 | 3/4 - 7/8 | 7 7/8 | 25 1/4 | 5 3/32 | 8 9/32 | 2 3/4 | 9 9/32 | 66.1 | ||||||||||

| BKOFFSH0815 | 15 | 24 - 26 | 200 | 663 | 142 | 210 | 70 | 236 | 29.5 | ||||||||||

| BKOFFSH0815 | 15 | 1 | 7 7/8 | 26 3/32 | 5 19/32 | 8 9/32 | 2 3/4 | 9 9/32 | 65.0 | ||||||||||

| BKOFFSH1008 | 8 | 20 - 22 | 250 | 606 | 103 | 260 | 46 | 165 | 25.4 | ||||||||||

| BKOFFSH1008 | 8 | 3/4 - 7/8 | 9 27/32 | 23 27/32 | 4 1/16 | 10 1/4 | 1 13/16 | 6 1/2 | 56.1 | ||||||||||

| BKOFFSH1012 | 12 | 20 - 22 | 250 | 728 | 125 | 260 | 70 | 236 | 35.5 | ||||||||||

| BKOFFSH1012 | 12 | 3/4 - 7/8 | 9 27/32 | 28 21/32 | 4 29/32 | 10 1/4 | 2 3/4 | 9 9/32 | 78.3 | ||||||||||

| BKOFFSH1015 | 15 | 24 - 26 | 250 | 745 | 166 | 260 | 70 | 236 | 41.0 | ||||||||||

| BKOFFSH1015 | 15 | 1 | 9 27/32 | 29 11/32 | 6 17/32 | 10 1/4 | 2 3/4 | 9 9/32 | 90.4 | ||||||||||

| BKOFFSH1208 | 8 | 20 - 22 | 300 | 671 | 119 | 310 | 46 | 165 | 32.0 | ||||||||||

| BKOFFSH1208 | 8 | 3/4 - 7/8 | 11 13/16 | 26 13/32 | 4 11/16 | 12 7/32 | 1 13/16 | 6 1/2 | 70.6 | ||||||||||

| BKOFFSH1212 | 12 | 20 - 22 | 300 | 810 | 166 | 310 | 70 | 236 | 50.0 | ||||||||||

| BKOFFSH1212 | 12 | 3/4 - 7/8 | 11 13/16 | 31 7/8 | 6 17/32 | 12 7/32 | 2 3/4 | 9 9/32 | 110 | ||||||||||

| BKOFFSH1215 | 15 | 24 - 26 | 300 | 810 | 166 | 310 | 70 | 236 | 52.0 | ||||||||||

| BKOFFSH1215 | 15 | 1 | 11 13/16 | 31 7/8 | 6 17/32 | 12 7/32 | 2 3/4 | 9 9/32 | 115 | ||||||||||

| BKOFFSH1408 | 8 | 20 - 22 | 350 | 716 | 119 | 360 | 46 | 165 | 38.0 | ||||||||||

| BKOFFSH1408 | 8 | 3/4 - 7/8 | 13 25/32 | 28 3/16 | 4 11/16 | 14 3/16 | 1 13/16 | 6 1/2 | 83.8 | ||||||||||

| BKOFFSH1412 | 12 | 20 - 22 | 350 | 835 | 166 | 360 | 70 | 236 | 59.0 | ||||||||||

| BKOFFSH1412 | 12 | 3/4 - 7/8 | 13 25/32 | 32 7/8 | 6 17/32 | 14 3/16 | 2 3/4 | 9 9/32 | 130 | ||||||||||

| BKOFFSH1415 | 15 | 24 - 26 | 350 | 837 | 166 | 360 | 70 | 236 | 58.5 | ||||||||||

| BKOFFSH1415 | 15 | 1 | 13 25/32 | 32 15/16 | 6 17/32 | 14 3/16 | 2 3/4 | 9 9/32 | 129 | ||||||||||

| BKOFFSH1608 | 8 | 20 - 22 | 400 | 780 | 119 | 415 | 46 | 165 | 48.0 | ||||||||||

| BKOFFSH1608 | 8 | 3/4 - 7/8 | 15 3/4 | 30 23/32 | 4 11/16 | 16 11/32 | 1 13/16 | 6 1/2 | 106 | ||||||||||

| BKOFFSH1612 | 12 | 20 - 22 | 400 | 888 | 166 | 415 | 70 | 236 | 36 | ||||||||||

| BKOFFSH1612 | 12 | 3/4 - 7/8 | 15 3/4 | 34 31/32 | 6 17/32 | 16 11/32 | 2 3/4 | 9 9/32 | 79.4 | ||||||||||

| BKOFFSH1615 | 15 | 24 - 26 | 400 | 890 | 166 | 415 | 70 | 236 | 68.5 | ||||||||||

| BKOFFSH1615 | 15 | 1 | 15 3/4 | 35 1/32 | 6 17/32 | 16 11/32 | 2 3/4 | 9 9/32 | 151 | ||||||||||

| BKOFFSH1808 | 8 | 20 - 22 | 450 | 841 | 119 | 465 | 46 | 165 | 58.0 | ||||||||||

| BKOFFSH1808 | 8 | 3/4 - 7/8 | 17 23/32 | 33 1/8 | 4 11/16 | 18 5/16 | 1 13/16 | 6 1/2 | 128 | ||||||||||

| BKOFFSH1812 | 12 | 20 - 22 | 450 | 942 | 166 | 465 | 70 | 236 | 42 | ||||||||||

| BKOFFSH1812 | 12 | 3/4 - 7/8 | 17 23/32 | 37 3/32 | 6 17/32 | 18 5/16 | 2 3/4 | 9 9/32 | 92.6 | ||||||||||

| BKOFFSH1815 | 15 | 24 - 26 | 450 | 942 | 166 | 465 | 70 | 236 | 82.0 | ||||||||||

| BKOFFSH1815 | 15 | 1 | 17 23/32 | 37 3/32 | 6 17/32 | 18 5/16 | 2 3/4 | 9 9/32 | 181 |

Frequently Asked Questions

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

FAQ-Reference PI-07-02 Rev. B

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

Snatch block type 601HK with Hook attached

Highlights

Smooth, uninterrupted pull due to conical roller bearings

Smooth, uninterrupted pull due to conical roller bearings

Coating assures long-term durability

Coating assures long-term durability

Lightweight

Lightweight

Superior stock availability of 99%

Superior stock availability of 99%

Reliable Green Pin® quality and support

Reliable Green Pin® quality and support

Description

The Green Pin® Snatch Block HK is a light-weight snatch block type 601HK with a hook attached. The snatch block has a smooth, uninterrupted pull due to the conical roller bearings. The coating of the Green Pin® Snatch Block HK ensures long-term durability, even under harsh conditions. It is available in a range with a working load limit from 2 up to 15 ton.

Product details

- ProductcodeP-6952

- Materialcarbon steel, fitted with conical roller bearings

- Safety factorMBL equals 4 x WLL

- Finishpainted

- Certification 2.1 2.2 MTCb CE

- NoteWorking Load Limit is on the headfitting

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope |

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH0302 | 2 | 7 - 9 | 75 | 290 | 87 | 82 | 28 | 108 | 3.68 |

| BKOFFSH0404 | 4 | 10 - 12 | 115 | 358 | 89 | 120 | 43 | 125 | 6.00 |

| BKOFFSH0604 | 4 | 12 - 14 | 150 | 412 | 89 | 160 | 40 | 125 | 8.50 |

| BKOFFSH0608 | 8 | 20 - 22 | 150 | 502 | 119 | 160 | 48 | 165 | 11.8 |

| BKOFFSH0612 | 12 | 20 - 22 | 150 | 616 | 119 | 160 | 70 | 236 | 20.5 |

| BKOFFSH0615 | 15 | 24 - 26 | 150 | 626 | 138 | 160 | 70 | 236 | 23.4 |

| BKOFFSH0804 | 4 | 10 - 12 | 200 | 473 | 91 | 210 | 40 | 125 | 8 |

| BKOFFSH0808 | 8 | 20 - 22 | 200 | 551 | 119 | 210 | 48 | 165 | 20.4 |

| BKOFFSH0812 | 12 | 20 - 22 | 200 | 641 | 129 | 210 | 70 | 236 | 30.0 |

| BKOFFSH0815 | 15 | 24 - 26 | 200 | 663 | 142 | 210 | 70 | 236 | 29.5 |

| BKOFFSH1008 | 8 | 20 - 22 | 250 | 606 | 103 | 260 | 46 | 165 | 25.4 |

| BKOFFSH1012 | 12 | 20 - 22 | 250 | 728 | 125 | 260 | 70 | 236 | 35.5 |

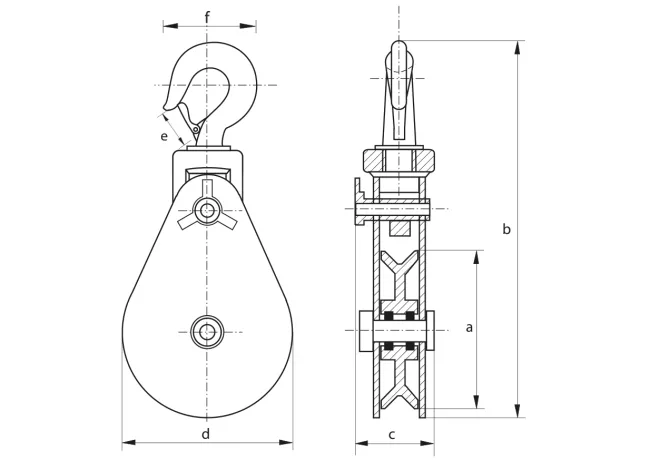

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope |

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH1015 | 15 | 24 - 26 | 250 | 745 | 166 | 260 | 70 | 236 | 41.0 |

| BKOFFSH1208 | 8 | 20 - 22 | 300 | 671 | 119 | 310 | 46 | 165 | 32.0 |

| BKOFFSH1212 | 12 | 20 - 22 | 300 | 810 | 166 | 310 | 70 | 236 | 50.0 |

| BKOFFSH1215 | 15 | 24 - 26 | 300 | 810 | 166 | 310 | 70 | 236 | 52.0 |

| BKOFFSH1408 | 8 | 20 - 22 | 350 | 716 | 119 | 360 | 46 | 165 | 38.0 |

| BKOFFSH1412 | 12 | 20 - 22 | 350 | 835 | 166 | 360 | 70 | 236 | 59.0 |

| BKOFFSH1415 | 15 | 24 - 26 | 350 | 837 | 166 | 360 | 70 | 236 | 58.5 |

| BKOFFSH1608 | 8 | 20 - 22 | 400 | 780 | 119 | 415 | 46 | 165 | 48.0 |

| BKOFFSH1612 | 12 | 20 - 22 | 400 | 888 | 166 | 415 | 70 | 236 | 36 |

| BKOFFSH1615 | 15 | 24 - 26 | 400 | 890 | 166 | 415 | 70 | 236 | 68.5 |

| BKOFFSH1808 | 8 | 20 - 22 | 450 | 841 | 119 | 465 | 46 | 165 | 58.0 |

| BKOFFSH1812 | 12 | 20 - 22 | 450 | 942 | 166 | 465 | 70 | 236 | 42 |

| BKOFFSH1815 | 15 | 24 - 26 | 450 | 942 | 166 | 465 | 70 | 236 | 82.0 |

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope |

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH1815 | 15 | 24 - 26 | 450 | 942 | 166 | 465 | 70 | 236 | 82.0 |

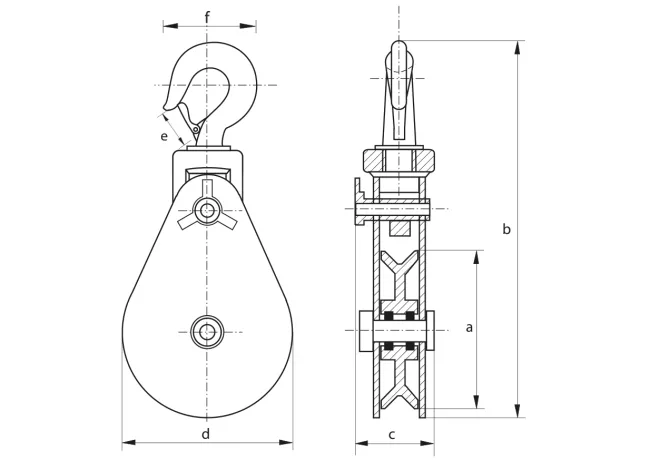

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope (inch) |

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH0302 | 2 | 9/32 - 3/8 | 2 15/16 | 11 13/32 | 3 7/16 | 3 7/32 | 1 3/32 | 4 1/4 | 8.12 |

| BKOFFSH0404 | 4 | 3/8 - 1/2 | 4 17/32 | 14 3/32 | 3 1/2 | 4 23/32 | 1 11/16 | 4 29/32 | 13.2 |

| BKOFFSH0604 | 4 | 1/2 - 9/16 | 5 29/32 | 16 7/32 | 3 1/2 | 6 5/16 | 1 9/16 | 4 29/32 | 18.7 |

| BKOFFSH0608 | 8 | 3/4 - 7/8 | 5 29/32 | 19 3/4 | 4 11/16 | 6 5/16 | 1 7/8 | 6 1/2 | 26.0 |

| BKOFFSH0612 | 12 | 3/4 - 7/8 | 5 29/32 | 24 1/4 | 4 11/16 | 6 5/16 | 2 3/4 | 9 9/32 | 45.2 |

| BKOFFSH0615 | 15 | 1 | 5 29/32 | 24 21/32 | 5 7/16 | 6 5/16 | 2 3/4 | 9 9/32 | 51.6 |

| BKOFFSH0804 | 4 | 3/8 - 15/32 | 7 7/8 | 18 5/8 | 3 19/32 | 8 9/32 | 1 9/16 | 4 29/32 | 17.6 |

| BKOFFSH0808 | 8 | 3/4 - 7/8 | 7 7/8 | 21 11/16 | 4 11/16 | 8 9/32 | 1 7/8 | 6 1/2 | 44.9 |

| BKOFFSH0812 | 12 | 3/4 - 7/8 | 7 7/8 | 25 1/4 | 5 3/32 | 8 9/32 | 2 3/4 | 9 9/32 | 66.1 |

| BKOFFSH0815 | 15 | 1 | 7 7/8 | 26 3/32 | 5 19/32 | 8 9/32 | 2 3/4 | 9 9/32 | 65.0 |

| BKOFFSH1008 | 8 | 3/4 - 7/8 | 9 27/32 | 23 27/32 | 4 1/16 | 10 1/4 | 1 13/16 | 6 1/2 | 56.1 |

| BKOFFSH1012 | 12 | 3/4 - 7/8 | 9 27/32 | 28 21/32 | 4 29/32 | 10 1/4 | 2 3/4 | 9 9/32 | 78.3 |

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope (inch) |

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH1015 | 15 | 1 | 9 27/32 | 29 11/32 | 6 17/32 | 10 1/4 | 2 3/4 | 9 9/32 | 90.4 |

| BKOFFSH1208 | 8 | 3/4 - 7/8 | 11 13/16 | 26 13/32 | 4 11/16 | 12 7/32 | 1 13/16 | 6 1/2 | 70.6 |

| BKOFFSH1212 | 12 | 3/4 - 7/8 | 11 13/16 | 31 7/8 | 6 17/32 | 12 7/32 | 2 3/4 | 9 9/32 | 110 |

| BKOFFSH1215 | 15 | 1 | 11 13/16 | 31 7/8 | 6 17/32 | 12 7/32 | 2 3/4 | 9 9/32 | 115 |

| BKOFFSH1408 | 8 | 3/4 - 7/8 | 13 25/32 | 28 3/16 | 4 11/16 | 14 3/16 | 1 13/16 | 6 1/2 | 83.8 |

| BKOFFSH1412 | 12 | 3/4 - 7/8 | 13 25/32 | 32 7/8 | 6 17/32 | 14 3/16 | 2 3/4 | 9 9/32 | 130 |

| BKOFFSH1415 | 15 | 1 | 13 25/32 | 32 15/16 | 6 17/32 | 14 3/16 | 2 3/4 | 9 9/32 | 129 |

| BKOFFSH1608 | 8 | 3/4 - 7/8 | 15 3/4 | 30 23/32 | 4 11/16 | 16 11/32 | 1 13/16 | 6 1/2 | 106 |

| BKOFFSH1612 | 12 | 3/4 - 7/8 | 15 3/4 | 34 31/32 | 6 17/32 | 16 11/32 | 2 3/4 | 9 9/32 | 79.4 |

| BKOFFSH1615 | 15 | 1 | 15 3/4 | 35 1/32 | 6 17/32 | 16 11/32 | 2 3/4 | 9 9/32 | 151 |

| BKOFFSH1808 | 8 | 3/4 - 7/8 | 17 23/32 | 33 1/8 | 4 11/16 | 18 5/16 | 1 13/16 | 6 1/2 | 128 |

| BKOFFSH1812 | 12 | 3/4 - 7/8 | 17 23/32 | 37 3/32 | 6 17/32 | 18 5/16 | 2 3/4 | 9 9/32 | 92.6 |

| BKOFFSH1815 | 15 | 1 | 17 23/32 | 37 3/32 | 6 17/32 | 18 5/16 | 2 3/4 | 9 9/32 | 181 |

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK

| Article code | working load limit | diameter wire rope (inch) |

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|

| BKOFFSH1815 | 15 | 1 | 17 23/32 | 37 3/32 | 6 17/32 | 18 5/16 | 2 3/4 | 9 9/32 | 181 |

Green Pin® Snatch Block HK

Green Pin® Snatch Block HK