Green Pin® Sling Hook E

Grade 10 eye sling hook

- Highlights

- Superior stock availability of 99%

- Reliable Green Pin® quality and support

The Green Pin® Sling Hook E is a grade 10 eye sling hook. The sling hook can be used for general lifting applications. It can be quickly connected to the load lifting points thanks to its easy operating latch, which guarantees full safety. To connect simply push the latch, connect the hook to the lifting point, and release the latch. The forged latch guarantees a longer lifespan. It strongly limits the risk that the operator uses the hook without latch. The latch is fitted with a stainless steel spring and a sturdy pin. The eye of the hook can be connected to grade 10 chain with a connecting link or an omega link, to a webbing with a web sling connector or to a wire rope with a thimble. The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Sling Hook E is available in a range to suit 6 mm up to 20 mm grade 10 chain.

More-

ProductcodeUCSO

-

Materialalloy steel, Grade 10, quenched and tempered

-

Safety factorMBL equals 4 x WLL

-

Finishpainted blue

-

Temp. range-40°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- MTCa

- MPIb

- DGUV

-

Notefrom 10 t without flat part

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

for chain diameter

(mm)

|

for chain diameter (inch)

|

length

(mm)

A

|

length (inch)

A

|

diameter eye inside

(mm)

B

|

diameter eye inside (inch)

B

|

opening hook (inch)

C

|

opening hook

(mm)

C

|

thickness

(mm)

D

|

thickness (inch)

D

|

width (inch)

E

|

width

(mm)

E

|

diameter eye outside (inch)

F

|

diameter eye outside

(mm)

F

|

width outside (inch)

G

|

width outside

(mm)

G

|

length (inch)

H

|

length

(mm)

H

|

width (inch)

I

|

width

(mm)

I

|

thickness (inch)

J

|

thickness

(mm)

J

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPUCSO10 | 4 | 10 | 129 | 36 | 33 | 24 | 28 | 65 | 106 | 171 | 15 | 10 | 1.09 | ||||||||||||||

| GPUCSO10 | 4 | 3/8 | 5 3/32 | 1 13/32 | 1 5/16 | 15/16 | 1 3/32 | 2 9/16 | 4 3/16 | 6 23/32 | 19/32 | 13/32 | 2.40 | ||||||||||||||

| GPUCSO13 | 6,8 | 13 | 152 | 41 | 37 | 32 | 39 | 77 | 133 | 209 | 18 | 12 | 1.94 | ||||||||||||||

| GPUCSO13 | 6,8 | 1/2 | 5 31/32 | 1 5/8 | 1 15/32 | 1 1/4 | 1 17/32 | 3 1/32 | 5 1/4 | 8 7/32 | 23/32 | 15/32 | 4.28 | ||||||||||||||

| GPUCSO16 | 10,3 | 16 | 191 | 52 | 43 | 40 | 43 | 94 | 165 | 255 | 21 | 17 | 3.51 | ||||||||||||||

| GPUCSO16 | 10,3 | 5/8 | 7 17/32 | 2 1/16 | 1 11/16 | 1 9/16 | 1 11/16 | 3 11/16 | 6 1/2 | 10 1/32 | 13/16 | 5/8 | 7.74 | ||||||||||||||

| GPUCSO20 | 16 | 20 | 237 | 61 | 61 | 49 | 61 | 115 | 208 | 326 | 28 | 21 | 7.08 | ||||||||||||||

| GPUCSO20 | 16 | 3/4 | 9 11/32 | 2 13/32 | 2 13/32 | 1 15/16 | 2 13/32 | 4 17/32 | 8 3/16 | 12 27/32 | 1 3/32 | 13/16 | 15.6 | ||||||||||||||

| GPUCSO6 | 1,4 | 6 | 86 | 23 | 26 | 15 | 19 | 43 | 73 | 114 | 10 | 6 | 0.28 | ||||||||||||||

| GPUCSO6 | 1,4 | 7/32 | 3 5/16 | 29/32 | 1 1/32 | 19/32 | 3/4 | 1 11/16 | 2 27/32 | 4 1/2 | 13/32 | 1/4 | 0.63 | ||||||||||||||

| GPUCSO8 | 2,6 | 8 | 103 | 26 | 30 | 19 | 24 | 51 | 87 | 139 | 12 | 8 | 0.52 | ||||||||||||||

| GPUCSO8 | 2,6 | 5/16 | 4 1/16 | 1 1/32 | 1 3/16 | 25/32 | 15/16 | 2 | 3 7/16 | 5 15/32 | 15/32 | 5/16 | 1.14 |

Frequently Asked Questions

DGUV Type Approval

Van Beest puts great emphasis on the quality of products. Recently, we have renewed our DGUV Type Approvals for many of our products. This allows us to H-stamp the components with our unique H number (H94).

DGUV (Deutsche Gesetzliche Unfallversicherung / German Social Accident Insurance) is the umbrella association of the accident insurance institutions for the industrial and public sectors, a leading certification association in Europe.

The test procedure includes verification of materials, verification of the dimensions on individual samples, tensile tests, fatigue tests and some specific tests such as a bending test, a latch lock test and a latch strength test. The results are compared to the specifications mentioned in the EN 1677 norm. With this comprehensive testing procedure and certification of both chain and components, Van Beest supplies the highest quality products that contribute to a safe working environment. Click here to download all the certificates.

You can find the Working Load Limit tables for chain assemblies here:

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

FAQ-Reference PI-07-02 Rev. B

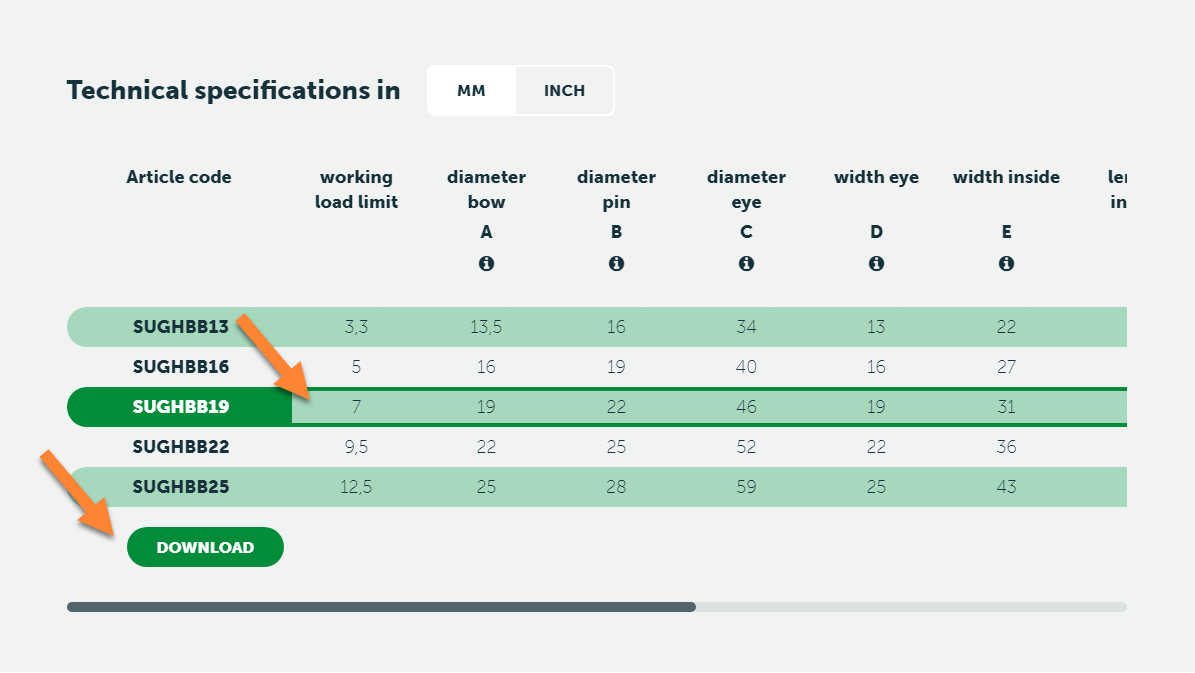

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

Please find the user manual here.

Grade 10 eye sling hook

Highlights

Superior stock availability of 99%

Superior stock availability of 99%

Reliable Green Pin® quality and support

Reliable Green Pin® quality and support

Description

The Green Pin® Sling Hook E is a grade 10 eye sling hook. The sling hook can be used for general lifting applications. It can be quickly connected to the load lifting points thanks to its easy operating latch, which guarantees full safety. To connect simply push the latch, connect the hook to the lifting point, and release the latch. The forged latch guarantees a longer lifespan. It strongly limits the risk that the operator uses the hook without latch. The latch is fitted with a stainless steel spring and a sturdy pin. The eye of the hook can be connected to grade 10 chain with a connecting link or an omega link, to a webbing with a web sling connector or to a wire rope with a thimble. The flat on the eye enables the assembly with an omega link or on a thimble. The Green Pin® Sling Hook E is available in a range to suit 6 mm up to 20 mm grade 10 chain.

Product details

- ProductcodeUCSO

- Materialalloy steel, Grade 10, quenched and tempered

- Safety factorMBL equals 4 x WLL

- Finishpainted blue

- Certification 2.1 2.2 3.1 MTCa MPIb DGUV

- Notefrom 10 t without flat part

Green Pin® Sling Hook E

Green Pin® Sling Hook E

| Article code | working load limit | for chain diameter |

|

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPUCSO10 | 4 | 10 | 129 | 36 | 33 | 24 | 28 | 65 | 106 | 171 | 15 | 10 | 1.09 |

| GPUCSO13 | 6,8 | 13 | 152 | 41 | 37 | 32 | 39 | 77 | 133 | 209 | 18 | 12 | 1.94 |

| GPUCSO16 | 10,3 | 16 | 191 | 52 | 43 | 40 | 43 | 94 | 165 | 255 | 21 | 17 | 3.51 |

| GPUCSO20 | 16 | 20 | 237 | 61 | 61 | 49 | 61 | 115 | 208 | 326 | 28 | 21 | 7.08 |

| GPUCSO6 | 1,4 | 6 | 86 | 23 | 26 | 15 | 19 | 43 | 73 | 114 | 10 | 6 | 0.28 |

| GPUCSO8 | 2,6 | 8 | 103 | 26 | 30 | 19 | 24 | 51 | 87 | 139 | 12 | 8 | 0.52 |

Green Pin® Sling Hook E

Green Pin® Sling Hook E

| Article code | working load limit | for chain diameter (inch) |

|

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GPUCSO10 | 4 | 3/8 | 5 3/32 | 1 13/32 | 1 5/16 | 15/16 | 1 3/32 | 2 9/16 | 4 3/16 | 6 23/32 | 19/32 | 13/32 | 2.40 |

| GPUCSO13 | 6,8 | 1/2 | 5 31/32 | 1 5/8 | 1 15/32 | 1 1/4 | 1 17/32 | 3 1/32 | 5 1/4 | 8 7/32 | 23/32 | 15/32 | 4.28 |

| GPUCSO16 | 10,3 | 5/8 | 7 17/32 | 2 1/16 | 1 11/16 | 1 9/16 | 1 11/16 | 3 11/16 | 6 1/2 | 10 1/32 | 13/16 | 5/8 | 7.74 |

| GPUCSO20 | 16 | 3/4 | 9 11/32 | 2 13/32 | 2 13/32 | 1 15/16 | 2 13/32 | 4 17/32 | 8 3/16 | 12 27/32 | 1 3/32 | 13/16 | 15.6 |

| GPUCSO6 | 1,4 | 7/32 | 3 5/16 | 29/32 | 1 1/32 | 19/32 | 3/4 | 1 11/16 | 2 27/32 | 4 1/2 | 13/32 | 1/4 | 0.63 |

| GPUCSO8 | 2,6 | 5/16 | 4 1/16 | 1 1/32 | 1 3/16 | 25/32 | 15/16 | 2 | 3 7/16 | 5 15/32 | 15/32 | 5/16 | 1.14 |

Green Pin® Sling Hook E

Green Pin® Sling Hook E