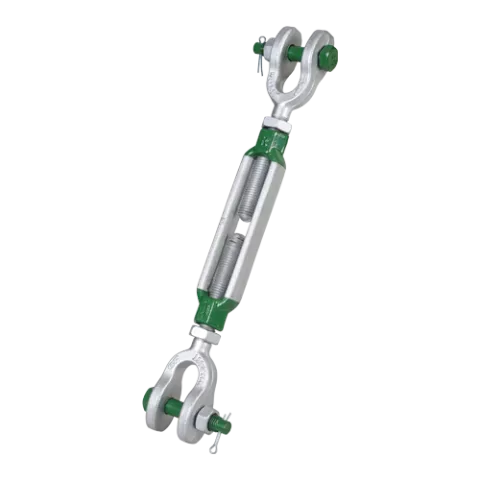

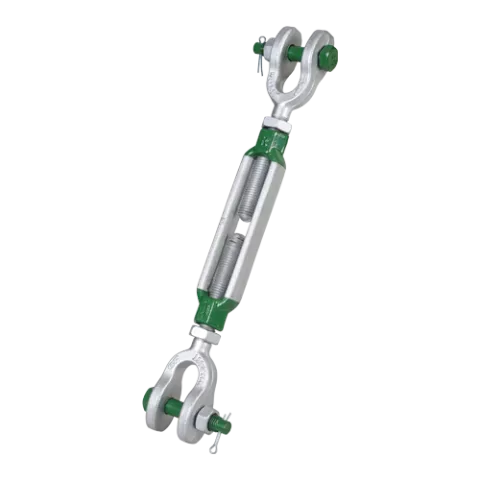

Green Pin® JJ Turnbuckle BN

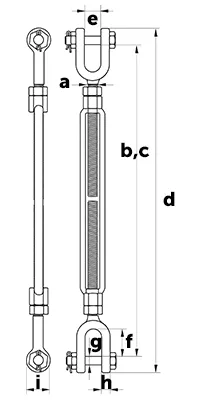

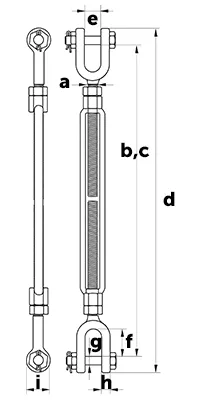

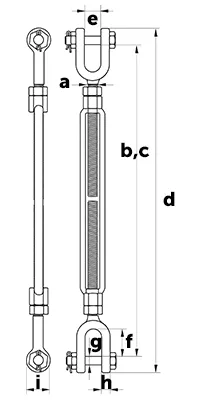

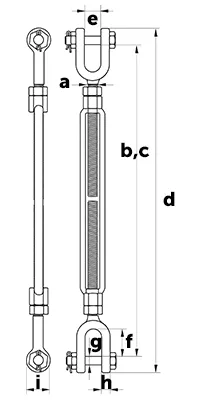

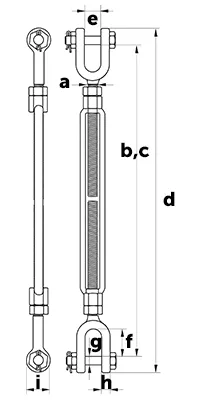

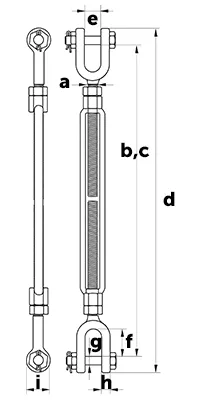

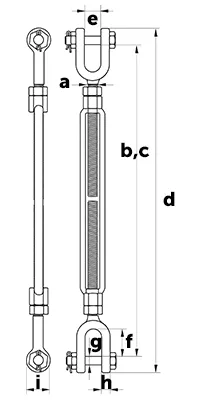

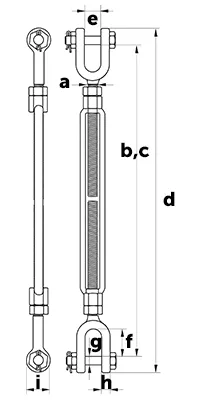

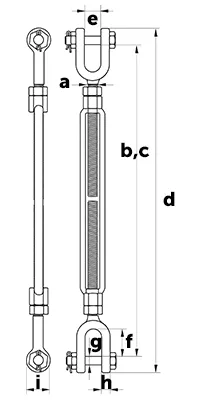

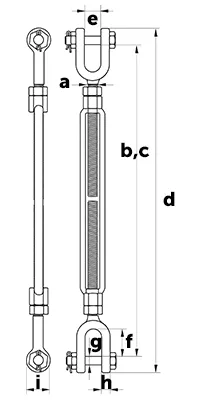

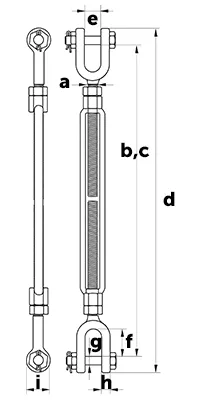

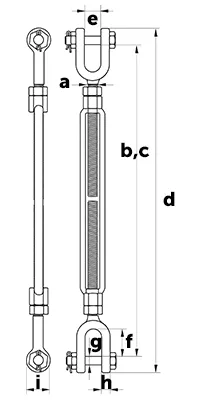

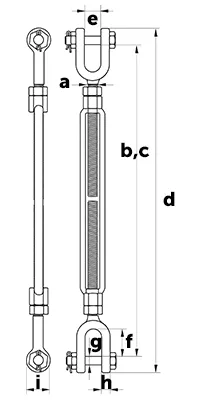

Turnbuckle with jaw-jaw end-fitting and safety bolt, generally to ASTM F1145-92

- Highlights

- Can be used for both lifting and lashing

- Double safety (cotter pin & safety bolt)

- Reliable Green Pin® quality and support

The Green Pin® JJ Turnbuckle BN is a turnbuckle with jaw-jaw end-fitting and a safety bolt, generally to ASTM F1145-92. One of the unique features of Green Pin® Turnbuckles such as this one is that they can be used for both lifting and lashing. The turnbuckle also offers a double safety (cotter pin and safety bolt) which prevents accidental unscrewing of the pin. The Green Pin® JJ Turnbuckle BN is available in a range with a diameter thread of 3/8" (take up of 6") up to 2 3/4" (take up of 24").

More-

ProductcodeG-6323

-

Materialdrop forged high tensile steel SAE 1035 or 1045

-

Safety factorMBL equals 5 x WLL

-

Finishhot dipped galvanized

-

Temp. range-20°C up to +200°C

-

Certification

- 2.1

- 2.2

- 3.1

- MTCa

- CE

-

Standardgenerally to ASTM F1145-92, formerly U.S. Federal Specification FF-T-791b

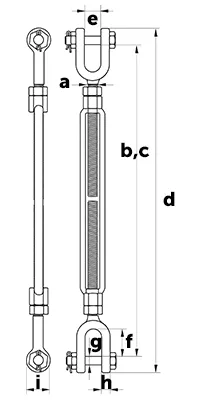

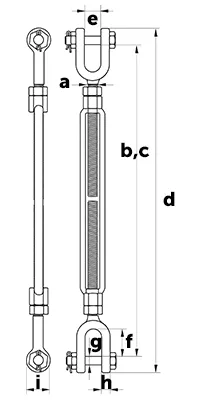

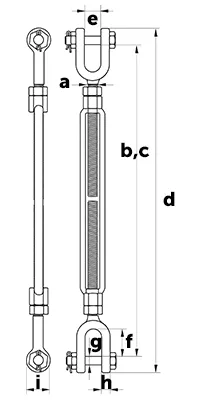

| Article code |

working load limit

(ton)

|

working load limit

(ton)

|

take up (inch)

|

take up (inch)

|

diameter thread (inch)

A

|

diameter thread (inch)

A

|

length closed position

(mm)

B

|

length closed position (inch)

B

|

length open position (inch)

C

|

length open position

(mm)

C

|

length closed position

(mm)

D

|

length closed position (inch)

D

|

opening jaw (inch)

E

|

opening jaw

(mm)

E

|

length inside (inch)

F

|

length inside

(mm)

F

|

diameter pin (inch)

G

|

diameter pin

(mm)

G

|

thickness jaw eye (inch)

H

|

thickness jaw eye

(mm)

H

|

diameter jaw eye (inch)

I

|

diameter jaw eye

(mm)

I

|

Net weight (KG) | Net weight (LBS) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPGG1006 | 0,54 | 6 | 3/8 | 273 | 409 | 304 | 12 | 21 | 7 | 9 | 21 | 0.55 | |||||||||||||

| SSGPGG1006 | 0,54 | 6 | 3/8 | 10 3/4 | 16 1/8 | 11 31/32 | 15/32 | 13/16 | 9/32 | 11/32 | 13/16 | 1.21 | |||||||||||||

| SSGPGG1206 | 1 | 6 | 1/2 | 304 | 435 | 343 | 16 | 26 | 10 | 11 | 25 | 0.97 | |||||||||||||

| SSGPGG1206 | 1 | 6 | 1/2 | 11 31/32 | 17 5/32 | 13 17/32 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 2.15 | |||||||||||||

| SSGPGG1209 | 1 | 9 | 1/2 | 379 | 588 | 418 | 16 | 26 | 10 | 11 | 25 | 1.15 | |||||||||||||

| SSGPGG1209 | 1 | 9 | 1/2 | 14 29/32 | 23 5/32 | 16 1/2 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 2.53 | |||||||||||||

| SSGPGG1212 | 1 | 12 | 1/2 | 455 | 740 | 494 | 16 | 26 | 10 | 11 | 25 | 1.46 | |||||||||||||

| SSGPGG1212 | 1 | 12 | 1/2 | 17 15/16 | 29 1/8 | 19 1/2 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 3.22 | |||||||||||||

| SSGPGG1606 | 1,59 | 6 | 5/8 | 346 | 469 | 406 | 18 | 32 | 13 | 14 | 33 | 1.75 | |||||||||||||

| SSGPGG1606 | 1,59 | 6 | 5/8 | 13 5/8 | 18 1/2 | 16 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 3.86 | |||||||||||||

| SSGPGG1609 | 1,59 | 9 | 5/8 | 421 | 622 | 480 | 18 | 32 | 13 | 14 | 33 | 2.14 | |||||||||||||

| SSGPGG1609 | 1,59 | 9 | 5/8 | 16 19/32 | 24 1/2 | 18 29/32 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 4.71 | |||||||||||||

| SSGPGG1612 | 1,59 | 12 | 5/8 | 498 | 774 | 557 | 18 | 32 | 13 | 14 | 33 | 2.43 | |||||||||||||

| SSGPGG1612 | 1,59 | 12 | 5/8 | 19 5/8 | 30 7/16 | 21 15/16 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 5.37 | |||||||||||||

| SSGPMBGG1906 | 2,36 | 6 | 3/4 | 369 | 487 | 439 | 24 | 38 | 16 | 16 | 41 | 2.70 | |||||||||||||

| SSGPMBGG1906 | 2,36 | 6 | 3/4 | 14 17/32 | 19 3/16 | 17 5/16 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 5.95 | |||||||||||||

| SSGPMBGG1909 | 2,36 | 9 | 3/4 | 444 | 640 | 514 | 24 | 38 | 16 | 16 | 41 | 3.23 | |||||||||||||

| SSGPMBGG1909 | 2,36 | 9 | 3/4 | 17 17/32 | 25 3/16 | 20 1/4 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 7.12 | |||||||||||||

| SSGPMBGG1912 | 2,36 | 12 | 3/4 | 520 | 792 | 590 | 24 | 38 | 16 | 16 | 41 | 3.57 | |||||||||||||

| SSGPMBGG1912 | 2,36 | 12 | 3/4 | 20 1/2 | 31 5/32 | 23 1/4 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 7.87 | |||||||||||||

| SSGPMBGG1918 | 2,36 | 18 | 3/4 | 670 | 1096 | 740 | 24 | 38 | 16 | 16 | 41 | 4.55 | |||||||||||||

| SSGPMBGG1918 | 2,36 | 18 | 3/4 | 26 11/32 | 43 5/32 | 29 1/8 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 10.0 | |||||||||||||

| SSGPMBGG2212 | 3,27 | 12 | 7/8 | 561 | 826 | 638 | 27 | 42 | 19 | 19 | 48 | 5.22 | |||||||||||||

| SSGPMBGG2212 | 3,27 | 12 | 7/8 | 22 3/32 | 32 17/32 | 25 1/8 | 1 3/32 | 1 11/16 | 3/4 | 3/4 | 1 29/32 | 11.5 | |||||||||||||

| SSGPMBGG2218 | 3,27 | 18 | 7/8 | 713 | 1132 | 790 | 27 | 42 | 19 | 19 | 48 | 6.56 | |||||||||||||

| SSGPMBGG2218 | 3,27 | 18 | 7/8 | 28 1/32 | 44 9/16 | 31 3/32 | 1 3/32 | 1 11/16 | 3/4 | 3/4 | 1 29/32 | 14.5 | |||||||||||||

| SSGPMBGG2506 | 4,54 | 6 | 1 | 447 | 554 | 532 | 31 | 50 | 22 | 20 | 54 | 5.54 | |||||||||||||

| SSGPMBGG2506 | 4,54 | 6 | 1 | 17 5/8 | 21 13/16 | 20 15/16 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 12.2 | |||||||||||||

| SSGPMBGG2512 | 4,54 | 12 | 1 | 598 | 859 | 683 | 31 | 50 | 22 | 20 | 54 | 6.70 | |||||||||||||

| SSGPMBGG2512 | 4,54 | 12 | 1 | 23 9/16 | 33 13/16 | 26 7/8 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 14.8 | |||||||||||||

| SSGPMBGG2518 | 4,54 | 18 | 1 | 750 | 1168 | 835 | 31 | 50 | 22 | 20 | 54 | 8.61 | |||||||||||||

| SSGPMBGG2518 | 4,54 | 18 | 1 | 29 17/32 | 46 | 32 7/8 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 19.0 | |||||||||||||

| SSGPMBGG2524 | 4,5 | 24 | 1 | 903 | 1470 | 988 | 31 | 50 | 22 | 20 | 54 | 8.87 | |||||||||||||

| SSGPMBGG2524 | 4,5 | 24 | 1 | 35 9/16 | 57 7/8 | 38 29/32 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 19.6 | |||||||||||||

| SSGPMBGG3212 | 6,9 | 12 | 1 1/4 | 643 | 916 | 748 | 44 | 71 | 28 | 26 | 68 | 11.9 | |||||||||||||

| SSGPMBGG3212 | 6,9 | 12 | 1 1/4 | 25 5/16 | 36 1/32 | 29 7/16 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 26.2 | |||||||||||||

| SSGPMBGG3218 | 6,9 | 18 | 1 1/4 | 805 | 1230 | 910 | 44 | 71 | 28 | 26 | 68 | 13.6 | |||||||||||||

| SSGPMBGG3218 | 6,9 | 18 | 1 1/4 | 31 23/32 | 48 7/8 | 35 13/16 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 30.0 | |||||||||||||

| SSGPMBGG3224 | 6,9 | 24 | 1 1/4 | 964 | 1541 | 1069 | 44 | 71 | 28 | 26 | 68 | 14.2 | |||||||||||||

| SSGPMBGG3224 | 6,9 | 24 | 1 1/4 | 37 15/16 | 60 11/16 | 42 3/32 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 31.3 | |||||||||||||

| SSGPMBGG3812 | 9,71 | 12 | 1 1/2 | 675 | 942 | 806 | 52 | 71 | 35 | 28 | 80 | 18.5 | |||||||||||||

| SSGPMBGG3812 | 9,71 | 12 | 1 1/2 | 26 9/16 | 37 3/32 | 31 3/4 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 40.7 | |||||||||||||

| SSGPMBGG3818 | 9,71 | 18 | 1 1/2 | 825 | 1244 | 956 | 52 | 71 | 35 | 28 | 80 | 19.3 | |||||||||||||

| SSGPMBGG3818 | 9,71 | 18 | 1 1/2 | 32 1/2 | 48 31/32 | 37 5/8 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 42.6 | |||||||||||||

| SSGPMBGG3824 | 9,71 | 24 | 1 1/2 | 980 | 1551 | 1111 | 52 | 71 | 35 | 28 | 80 | 22 | |||||||||||||

| SSGPMBGG3824 | 9,71 | 24 | 1 1/2 | 38 19/32 | 61 1/16 | 43 3/4 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 48.5 | |||||||||||||

| SSGPMBGG4518 | 12,7 | 18 | 1 3/4 | 938 | 1316 | 1092 | 60 | 86 | 41 | 33 | 90 | 29 | |||||||||||||

| SSGPMBGG4518 | 12,7 | 18 | 1 3/4 | 36 29/32 | 51 13/16 | 43 | 2 11/32 | 3 3/8 | 1 5/8 | 1 5/16 | 3 9/16 | 64.0 | |||||||||||||

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 1089 | 1621 | 1243 | 60 | 86 | 41 | 33 | 90 | 33 | |||||||||||||

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 42 7/8 | 63 13/16 | 48 15/16 | 2 11/32 | 3 3/8 | 1 5/8 | 1 5/16 | 3 9/16 | 72.8 | |||||||||||||

| SSGPMBGG5024 | 16,8 | 24 | 2 | 1153 | 1673 | 1338 | 63 | 93 | 50 | 40 | 107 | 50.0 | |||||||||||||

| SSGPMBGG5024 | 16,8 | 24 | 2 | 45 13/32 | 65 7/8 | 52 11/16 | 2 1/2 | 3 11/16 | 1 31/32 | 1 19/32 | 4 3/16 | 110 | |||||||||||||

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 1255 | 1831 | 1480 | 75 | 114 | 57 | 41 | 143 | 88 | |||||||||||||

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 49 13/32 | 72 3/32 | 58 9/32 | 2 15/16 | 4 1/2 | 2 1/4 | 1 5/8 | 5 5/8 | 194 | |||||||||||||

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 1348 | 1882 | 1604 | 90 | 110 | 70 | 41 | 158 | 109 | |||||||||||||

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 53 3/32 | 74 3/32 | 63 5/32 | 3 9/16 | 4 5/16 | 2 3/4 | 1 5/8 | 6 3/16 | 240 |

Frequently Asked Questions

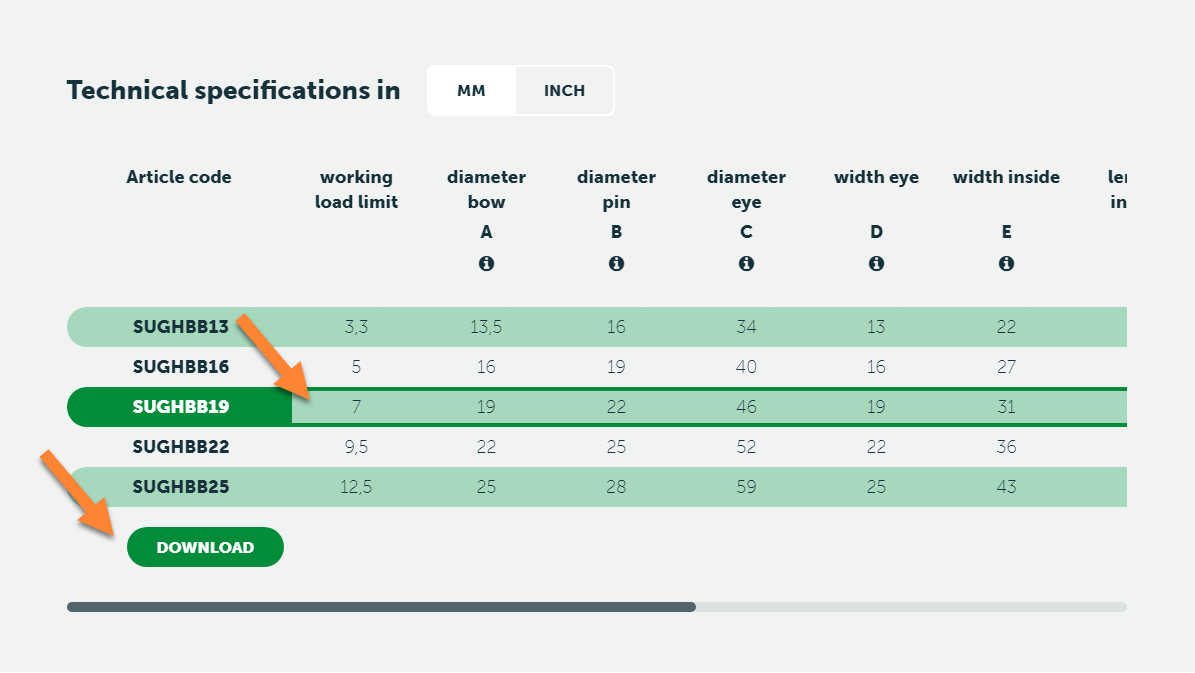

If you go to the product pages of individual products on this website, you can download the CAD-drawing (3D) of that product:

- On the product page, go to the table with dimensions

- Select the productsize that you are interested in

- A Download button will appear

If no Download button appears, no CAD-drawing for this product is available.

Green Pin® Turnbuckles G-6311, G-6312, G-6313, G-6314, G-6315, G-6323 and G-6333 are suitable for lifting applications. These items have a Proof Load equal to 2 x WLL and Minimum Breaking Load equals to 5x WLL. Of course the “Instructions for use”, as we publish them in our catalogue should be respected at all times.

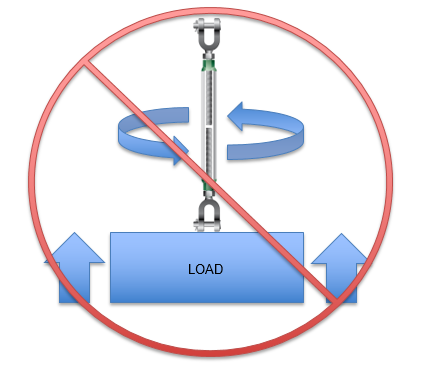

Note: It is not permitted to adjust the length of the turnbuckle under full load. Tensioning below the WLL is permitted. It is advisable first to adjust roughly the length of the turnbuckle and then load the turnbuckles to a certain tension. The tension may not exceed the full capacity (WLL).

Note: that it is not permitted to lift a load by tensioning (rotating the body) the turnbuckle, as shown in the picture below:

FAQ-Reference PI-02-01. Revision B.

No! Green Pin® products are treated with well designed heat treatment, which results in a certain Minimum Break Load and other specific mechanical properties. These properties will be destroyed by the heat of welding. It even can initiate extreme hard spots and initial cracks, that will decrease the strength and fatigue life dramatically. An exception is made for Green Pin® GH and PAS products, as these need to be welded to a surface to function. For these items, please follow the instructions that are available at Green Pin® sales.

FAQ-Reference PI-07-02 Rev. B

BN = Bolt & Nut, or safety bolt

CL = Clevis

CP = Cotter Pin

D = D-Handle

E = Eye

EE = Eye-Eye

EJ = Eye-Jaw

EH = Eye-Hook

F = F-Handle

FN = Fixed Nut

FP = Flush Pin

GR10 = Grade 10

GR5 = Grade 5

GR8 = Grade 8

HH = Hook-Hook

HK = Hook

H-type = Horizontal

JJ = Jaw-Jaw

ROV = Remotely Operated Vehicle

S = Shackle

S/S = Stainless Steel

SC = Screw Collar, or Screw Pin

SCL = Swivel Clevis

SE = Swivel Eye

SQ = Square headed Screw Pin

U-type = Universal (Horizontal and Vertical)

V-type = Vertical

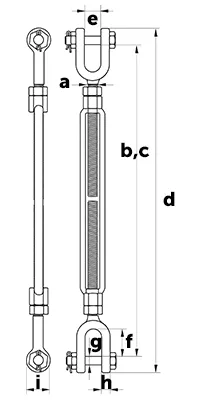

Turnbuckle with jaw-jaw end-fitting and safety bolt, generally to ASTM F1145-92

Highlights

Can be used for both lifting and lashing

Can be used for both lifting and lashing

Double safety (cotter pin & safety bolt)

Double safety (cotter pin & safety bolt)

Reliable Green Pin® quality and support

Reliable Green Pin® quality and support

Description

The Green Pin® JJ Turnbuckle BN is a turnbuckle with jaw-jaw end-fitting and a safety bolt, generally to ASTM F1145-92. One of the unique features of Green Pin® Turnbuckles such as this one is that they can be used for both lifting and lashing. The turnbuckle also offers a double safety (cotter pin and safety bolt) which prevents accidental unscrewing of the pin. The Green Pin® JJ Turnbuckle BN is available in a range with a diameter thread of 3/8" (take up of 6") up to 2 3/4" (take up of 24").

Product details

- ProductcodeG-6323

- Materialdrop forged high tensile steel SAE 1035 or 1045

- Safety factorMBL equals 5 x WLL

- Finishhot dipped galvanized

- Certification 2.1 2.2 3.1 MTCa CE

- Standardgenerally to ASTM F1145-92, formerly U.S. Federal Specification FF-T-791b

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPGG1006 | 0,54 | 6 | 3/8 | 273 | 409 | 304 | 12 | 21 | 7 | 9 | 21 | 0.55 |

| SSGPGG1206 | 1 | 6 | 1/2 | 304 | 435 | 343 | 16 | 26 | 10 | 11 | 25 | 0.97 |

| SSGPGG1209 | 1 | 9 | 1/2 | 379 | 588 | 418 | 16 | 26 | 10 | 11 | 25 | 1.15 |

| SSGPGG1212 | 1 | 12 | 1/2 | 455 | 740 | 494 | 16 | 26 | 10 | 11 | 25 | 1.46 |

| SSGPGG1606 | 1,59 | 6 | 5/8 | 346 | 469 | 406 | 18 | 32 | 13 | 14 | 33 | 1.75 |

| SSGPGG1609 | 1,59 | 9 | 5/8 | 421 | 622 | 480 | 18 | 32 | 13 | 14 | 33 | 2.14 |

| SSGPGG1612 | 1,59 | 12 | 5/8 | 498 | 774 | 557 | 18 | 32 | 13 | 14 | 33 | 2.43 |

| SSGPMBGG1906 | 2,36 | 6 | 3/4 | 369 | 487 | 439 | 24 | 38 | 16 | 16 | 41 | 2.70 |

| SSGPMBGG1909 | 2,36 | 9 | 3/4 | 444 | 640 | 514 | 24 | 38 | 16 | 16 | 41 | 3.23 |

| SSGPMBGG1912 | 2,36 | 12 | 3/4 | 520 | 792 | 590 | 24 | 38 | 16 | 16 | 41 | 3.57 |

| SSGPMBGG1918 | 2,36 | 18 | 3/4 | 670 | 1096 | 740 | 24 | 38 | 16 | 16 | 41 | 4.55 |

| SSGPMBGG2212 | 3,27 | 12 | 7/8 | 561 | 826 | 638 | 27 | 42 | 19 | 19 | 48 | 5.22 |

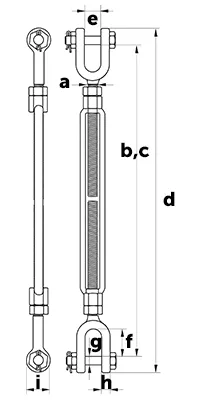

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPMBGG2218 | 3,27 | 18 | 7/8 | 713 | 1132 | 790 | 27 | 42 | 19 | 19 | 48 | 6.56 |

| SSGPMBGG2506 | 4,54 | 6 | 1 | 447 | 554 | 532 | 31 | 50 | 22 | 20 | 54 | 5.54 |

| SSGPMBGG2512 | 4,54 | 12 | 1 | 598 | 859 | 683 | 31 | 50 | 22 | 20 | 54 | 6.70 |

| SSGPMBGG2518 | 4,54 | 18 | 1 | 750 | 1168 | 835 | 31 | 50 | 22 | 20 | 54 | 8.61 |

| SSGPMBGG2524 | 4,5 | 24 | 1 | 903 | 1470 | 988 | 31 | 50 | 22 | 20 | 54 | 8.87 |

| SSGPMBGG3212 | 6,9 | 12 | 1 1/4 | 643 | 916 | 748 | 44 | 71 | 28 | 26 | 68 | 11.9 |

| SSGPMBGG3218 | 6,9 | 18 | 1 1/4 | 805 | 1230 | 910 | 44 | 71 | 28 | 26 | 68 | 13.6 |

| SSGPMBGG3224 | 6,9 | 24 | 1 1/4 | 964 | 1541 | 1069 | 44 | 71 | 28 | 26 | 68 | 14.2 |

| SSGPMBGG3812 | 9,71 | 12 | 1 1/2 | 675 | 942 | 806 | 52 | 71 | 35 | 28 | 80 | 18.5 |

| SSGPMBGG3818 | 9,71 | 18 | 1 1/2 | 825 | 1244 | 956 | 52 | 71 | 35 | 28 | 80 | 19.3 |

| SSGPMBGG3824 | 9,71 | 24 | 1 1/2 | 980 | 1551 | 1111 | 52 | 71 | 35 | 28 | 80 | 22 |

| SSGPMBGG4518 | 12,7 | 18 | 1 3/4 | 938 | 1316 | 1092 | 60 | 86 | 41 | 33 | 90 | 29 |

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 1089 | 1621 | 1243 | 60 | 86 | 41 | 33 | 90 | 33 |

| SSGPMBGG5024 | 16,8 | 24 | 2 | 1153 | 1673 | 1338 | 63 | 93 | 50 | 40 | 107 | 50.0 |

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 1255 | 1831 | 1480 | 75 | 114 | 57 | 41 | 143 | 88 |

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 1348 | 1882 | 1604 | 90 | 110 | 70 | 41 | 158 | 109 |

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 1089 | 1621 | 1243 | 60 | 86 | 41 | 33 | 90 | 33 |

| SSGPMBGG5024 | 16,8 | 24 | 2 | 1153 | 1673 | 1338 | 63 | 93 | 50 | 40 | 107 | 50.0 |

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 1255 | 1831 | 1480 | 75 | 114 | 57 | 41 | 143 | 88 |

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 1348 | 1882 | 1604 | 90 | 110 | 70 | 41 | 158 | 109 |

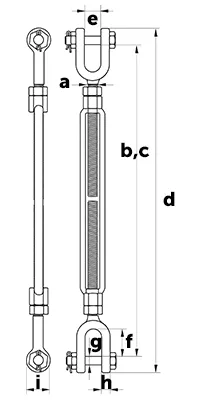

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPGG1006 | 0,54 | 6 | 3/8 | 10 3/4 | 16 1/8 | 11 31/32 | 15/32 | 13/16 | 9/32 | 11/32 | 13/16 | 1.21 |

| SSGPGG1206 | 1 | 6 | 1/2 | 11 31/32 | 17 5/32 | 13 17/32 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 2.15 |

| SSGPGG1209 | 1 | 9 | 1/2 | 14 29/32 | 23 5/32 | 16 1/2 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 2.53 |

| SSGPGG1212 | 1 | 12 | 1/2 | 17 15/16 | 29 1/8 | 19 1/2 | 5/8 | 1 1/32 | 13/32 | 7/16 | 1 | 3.22 |

| SSGPGG1606 | 1,59 | 6 | 5/8 | 13 5/8 | 18 1/2 | 16 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 3.86 |

| SSGPGG1609 | 1,59 | 9 | 5/8 | 16 19/32 | 24 1/2 | 18 29/32 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 4.71 |

| SSGPGG1612 | 1,59 | 12 | 5/8 | 19 5/8 | 30 7/16 | 21 15/16 | 23/32 | 1 9/32 | 1/2 | 9/16 | 1 5/16 | 5.37 |

| SSGPMBGG1906 | 2,36 | 6 | 3/4 | 14 17/32 | 19 3/16 | 17 5/16 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 5.95 |

| SSGPMBGG1909 | 2,36 | 9 | 3/4 | 17 17/32 | 25 3/16 | 20 1/4 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 7.12 |

| SSGPMBGG1912 | 2,36 | 12 | 3/4 | 20 1/2 | 31 5/32 | 23 1/4 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 7.87 |

| SSGPMBGG1918 | 2,36 | 18 | 3/4 | 26 11/32 | 43 5/32 | 29 1/8 | 15/16 | 1 17/32 | 5/8 | 5/8 | 1 5/8 | 10.0 |

| SSGPMBGG2212 | 3,27 | 12 | 7/8 | 22 3/32 | 32 17/32 | 25 1/8 | 1 3/32 | 1 11/16 | 3/4 | 3/4 | 1 29/32 | 11.5 |

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPMBGG2218 | 3,27 | 18 | 7/8 | 28 1/32 | 44 9/16 | 31 3/32 | 1 3/32 | 1 11/16 | 3/4 | 3/4 | 1 29/32 | 14.5 |

| SSGPMBGG2506 | 4,54 | 6 | 1 | 17 5/8 | 21 13/16 | 20 15/16 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 12.2 |

| SSGPMBGG2512 | 4,54 | 12 | 1 | 23 9/16 | 33 13/16 | 26 7/8 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 14.8 |

| SSGPMBGG2518 | 4,54 | 18 | 1 | 29 17/32 | 46 | 32 7/8 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 19.0 |

| SSGPMBGG2524 | 4,5 | 24 | 1 | 35 9/16 | 57 7/8 | 38 29/32 | 1 1/4 | 1 31/32 | 7/8 | 25/32 | 2 1/8 | 19.6 |

| SSGPMBGG3212 | 6,9 | 12 | 1 1/4 | 25 5/16 | 36 1/32 | 29 7/16 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 26.2 |

| SSGPMBGG3218 | 6,9 | 18 | 1 1/4 | 31 23/32 | 48 7/8 | 35 13/16 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 30.0 |

| SSGPMBGG3224 | 6,9 | 24 | 1 1/4 | 37 15/16 | 60 11/16 | 42 3/32 | 1 3/4 | 2 25/32 | 1 1/8 | 1 1/32 | 2 11/16 | 31.3 |

| SSGPMBGG3812 | 9,71 | 12 | 1 1/2 | 26 9/16 | 37 3/32 | 31 3/4 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 40.7 |

| SSGPMBGG3818 | 9,71 | 18 | 1 1/2 | 32 1/2 | 48 31/32 | 37 5/8 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 42.6 |

| SSGPMBGG3824 | 9,71 | 24 | 1 1/2 | 38 19/32 | 61 1/16 | 43 3/4 | 2 1/32 | 2 25/32 | 1 3/8 | 1 1/8 | 3 5/32 | 48.5 |

| SSGPMBGG4518 | 12,7 | 18 | 1 3/4 | 36 29/32 | 51 13/16 | 43 | 2 11/32 | 3 3/8 | 1 5/8 | 1 5/16 | 3 9/16 | 64.0 |

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 42 7/8 | 63 13/16 | 48 15/16 | 2 11/32 | 3 3/8 | 1 5/8 | 1 5/16 | 3 9/16 | 72.8 |

| SSGPMBGG5024 | 16,8 | 24 | 2 | 45 13/32 | 65 7/8 | 52 11/16 | 2 1/2 | 3 11/16 | 1 31/32 | 1 19/32 | 4 3/16 | 110 |

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 49 13/32 | 72 3/32 | 58 9/32 | 2 15/16 | 4 1/2 | 2 1/4 | 1 5/8 | 5 5/8 | 194 |

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 53 3/32 | 74 3/32 | 63 5/32 | 3 9/16 | 4 5/16 | 2 3/4 | 1 5/8 | 6 3/16 | 240 |

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN

| Article code | working load limit | take up (inch) |

|

|

|

|

|

|

|

|

|

Net weight

(LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSGPMBGG4524 | 12,7 | 24 | 1 3/4 | 42 7/8 | 63 13/16 | 48 15/16 | 2 11/32 | 3 3/8 | 1 5/8 | 1 5/16 | 3 9/16 | 72.8 |

| SSGPMBGG5024 | 16,8 | 24 | 2 | 45 13/32 | 65 7/8 | 52 11/16 | 2 1/2 | 3 11/16 | 1 31/32 | 1 19/32 | 4 3/16 | 110 |

| SSGPMBGG6424 | 27,2 | 24 | 2 1/2 | 49 13/32 | 72 3/32 | 58 9/32 | 2 15/16 | 4 1/2 | 2 1/4 | 1 5/8 | 5 5/8 | 194 |

| SSGPMBGG6924 | 34 | 24 | 2 3/4 | 53 3/32 | 74 3/32 | 63 5/32 | 3 9/16 | 4 5/16 | 2 3/4 | 1 5/8 | 6 3/16 | 240 |

Green Pin® JJ Turnbuckle BN

Green Pin® JJ Turnbuckle BN